In the intricate world of diesel engine maintenance, every component plays a pivotal role in ensuring the longevity and performance of the vehicle. Among these components, fuel systems and filters stand out as critical elements that deserve our attention. Think of the fuel system as the lifeblood of the engine, delivering the pristine fuel required for optimal performance.

The role of the lift pump, a low-pressure marvel that draws fuel from the tank to the injection system, cannot be understated. A malfunctioning lift pump can trigger a domino effect of issues, from sluggish starts to serious performance problems. This is where the significance of regular maintenance shines through, as a well-cared-for lift pump can enhance efficiency, protect against contaminants, and ultimately prolong the life of a diesel engine.

Understanding these intricate relationships becomes essential for anyone looking to maintain the integrity and reliability of their diesel vehicle. Let’s delve into the importance of these systems and discover how maintaining them can lead to a smoother, more reliable ride.

Lift Pump Functions in Diesel Engines

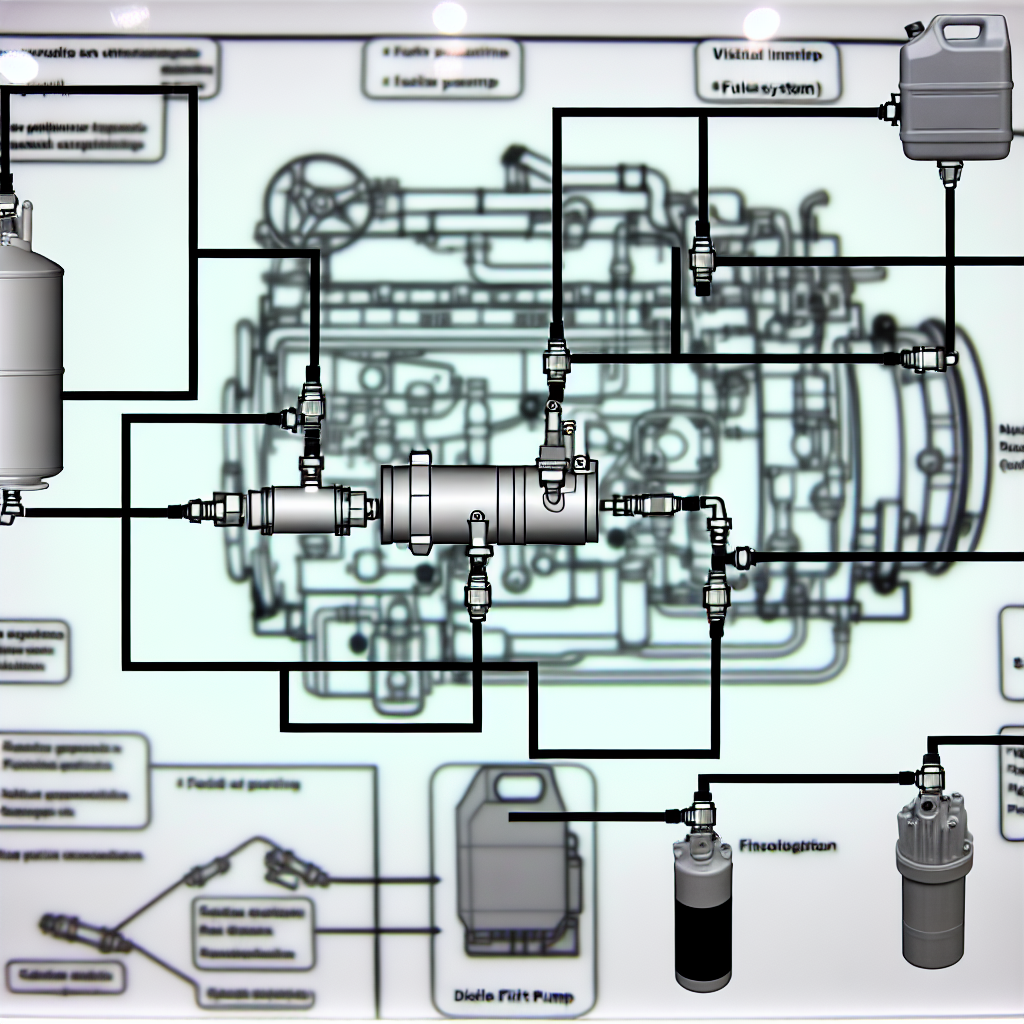

The lift pump is a vital part of a diesel engine’s fuel system. Its main job is to supply fuel from the tank to higher pressure components, such as fuel injectors. Operating at low pressure, generally between 5 and 10 psi, it ensures a steady fuel flow. In contrast, high-pressure fuel pumps can generate pressures exceeding 30,000 psi to atomize fuel for efficient combustion. The lift pump’s lower pressure protects the fuel system from excessive stress that could cause leaks and failures.

The lift pump plays a significant role in preventing fuel cavitation, ensuring constant fuel flow, and supporting reliable engine performance. If the lift pump fails, the engine might struggle to start, lose power, or experience fuel starvation during demanding conditions. Maintaining the lift pump is crucial because any issues in fuel delivery can lead to serious engine problems, such as misfiring and damage to the high-pressure pump. Regular maintenance checks, including filter replacements, help keep the lift pump functioning properly. This establishes the lift pump not just as a basic component but as an essential part influencing the entire diesel fuel system and engine performance.

In diesel engines, the fuel delivery system includes two key components: the lift pump and the high-pressure fuel pump. Both perform distinct but crucial roles for efficient engine operation.

Lift Pump Functions:

- Fuel Delivery: Guarantees a consistent fuel supply from the tank to the high-pressure pump, overcoming resistance from fuel lines and filters. (source)

- System Priming: Eliminates air pockets from the fuel system for easier engine starts, especially after maintenance or when fuel levels are low. (source)

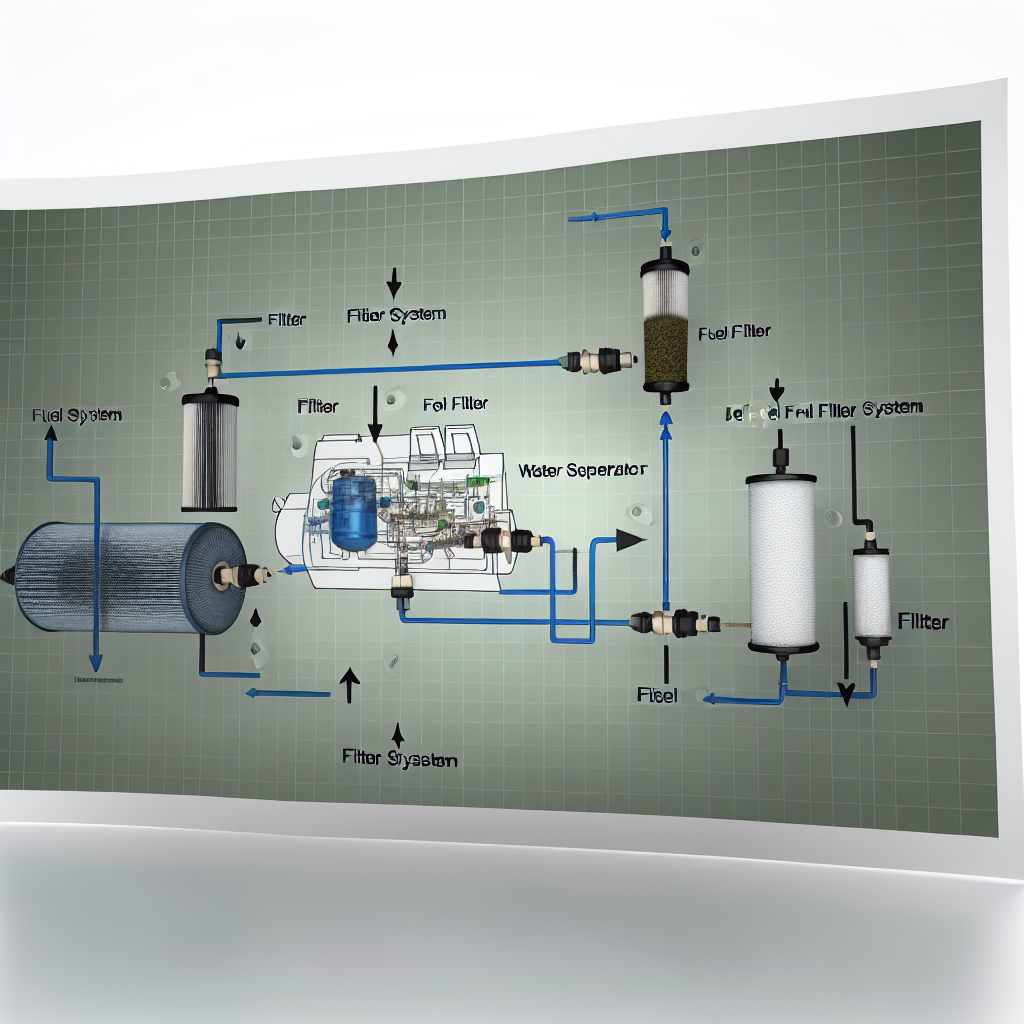

- Fuel Filtration: Often incorporates filters to remove contaminants before the fuel reaches the engine, protecting sensitive components. (source)

- Pressure Regulation: Maintains proper fuel pressure to meet engine needs, ensuring optimal combustion. (source)

High-Pressure Fuel Pump Functions:

Once the fuel reaches the high-pressure fuel pump, its tasks are:

- Fuel Pressurization: Increases fuel pressure to high levels (typically above 30,000 psi) needed for direct injection into combustion chambers. (source)

- Injection Timing and Quantity Control: Accurately regulates the timing and volume of fuel injected into each cylinder, enhancing combustion efficiency and engine performance.

Significance in Fuel Flow and Engine Performance:

- Preventing Fuel Starvation: A failing lift pump can lead to insufficient fuel supply, causing power loss, stalling, or engine failure. (source)

- Protecting Engine Components: Consistent fuel flow lubricates and cools the high-pressure pump and injectors, minimizing wear and extending their lifespan. (source)

- Enhancing Fuel Efficiency: Effective fuel delivery ensures complete combustion, improving fuel mileage and reducing emissions. (source)

In summary, while the lift pump ensures a steady fuel supply to the high-pressure pump, the latter elevates and delivers fuel for combustion. Both are crucial for maintaining optimal fuel flow and engine performance.

| Feature | Lift Pump | High-Pressure Fuel Pump |

|---|---|---|

| Function | Supplies fuel from the tank to the fuel system | Raises fuel pressure for injection into the combustion chamber |

| Pressure Range | Low pressure (typically 5 to 10 psi) | High pressure (up to 30,000 psi or more) |

| Installation Location | Between the fuel tank and high-pressure pump | Close to the engine, often integrated with the fuel rail |

| Typical Issues | Failures can lead to hard starts, reduced power, and fuel starvation; often affected by clogged filters | Issues can cause engine misfires, reduced efficiency, and in severe cases, damage to injectors or the pump itself |

Common Issues Caused by Lift Pump Failure

The lift pump is essential for drawing fuel from the tank to the high-pressure injection system. If it fails, various problems occur, affecting both performance and reliability:

- Difficulty Starting: A failing lift pump can lead to trouble starting the engine, as fuel delivery becomes insufficient. This may result in excessive cranking or an inability to start altogether.

- Poor Engine Performance: When the lift pump is deficient, power loss occurs. This is particularly noticeable under demanding conditions like towing or on inclines.

- Engine Misfires: Inconsistent fuel flow can trigger misfires and result in vibrations along with a rough idle. Left unchecked, this may lead to further mechanical issues.

- Increased Fuel Usage: A malfunctioning lift pump can lead to incomplete combustion, resulting in higher fuel consumption and emissions. This is costly and environmentally damaging.

- Unusual Noises: A failing lift pump may produce strange sounds like whining or grinding, signaling internal wear.

- Engine Overheating: Insufficient fuel supply causes the engine to overheat, putting stress on components and leading to severe failures if not managed.

In conclusion, lift pump failures can create significant problems impacting performance and potentially resulting in costly repairs. Regular checks and maintenance are crucial. As one expert put it, “A bad lift pump can cause a cascade of other issues that can lead to serious problems with a diesel car or truck.”

Maintenance Tips for Lift Pumps in Diesel Engines

To ensure the longevity and optimal performance of lift pumps in diesel engines, consider incorporating the following actionable maintenance tips:

- Use High-Quality Fuel: Sourcing high-quality diesel from reputable stations helps prevent contaminants like dirt and water that can cause wear. As noted, “High-quality diesel fuel can prevent contamination in the fuel system.”

- Regularly Replace Fuel Filters: Clogged filters can restrict fuel flow, putting excess stress on the lift pump. It is advisable to replace filters every 10,000 to 15,000 miles, or according to the manufacturer’s recommendations.

- Drain Water Separators: Water buildup in the fuel system can lead to corrosion and microbial growth. Regularly draining these separators helps avoid water ingress, ensuring the pump functions smoothly. As one expert mentioned, “The water not only causes corrosion but can also lead to some nasty microbes forming.”

- Monitor Fuel Pressure: Checking fuel pressure is essential for optimal lift pump operation. Too much or too little pressure can trigger performance issues or damage the pump over time. Regular pressure checks can prevent these complications.

- Prime the Pump After Maintenance: When performing maintenance or changing the fuel filter, always prime the pump to eliminate air pockets. Air in the fuel system can induce cavitation, leading to additional wear and potential failure.

Implementing these tips is crucial as, “Following some smart tips for diesel maintenance can go a long way in keeping a vehicle healthy,” reinforcing the importance of consistent care for the lift pump.

Conclusion

In conclusion, the significance of regular maintenance for diesel engines cannot be overstated, as it plays a critical role in extending the lifespan and enhancing the performance of these vehicles. Within the complex fuel system, lift pumps stand out as essential components that require consistent care to ensure optimal functionality.

By adhering to maintenance best practices such as using high-quality fuel, routinely replacing filters, and monitoring fuel pressure, vehicle owners can safeguard their diesel engines against common issues caused by lift pump failures. This proactive approach not only helps prevent performance bottlenecks and costly repairs but also creates a more reliable driving experience overall.

In essence, a well-maintained fuel system contributes to better fuel efficiency, reduced emissions, and a more resilient engine. Ultimately, investing time and resources into the upkeep of your diesel engine, particularly its fuel system and lift pumps, is paramount for achieving reliability, efficiency, and longevity on the road.

User Adoption Trends in Diesel Engine Maintenance Practices

Recent trends in diesel engine maintenance practices, particularly concerning lift pumps and fuel systems, indicate a growing emphasis on advanced technologies and predictive maintenance strategies. The following developments have been observed:

- Integration of Electronic Control Units (ECUs): By 2024, over 60% of new diesel fuel pump models incorporated ECUs, enabling real-time performance monitoring via CAN bus systems. This advancement facilitates proactive maintenance and enhances fuel system reliability.

- Adoption of Predictive Maintenance Protocols: The implementation of AI-powered diagnostics in injection pumps allows for the analysis of fuel flow patterns and pressure anomalies in real time. This approach minimizes downtime, optimizes fuel economy, and reduces long-term operational costs by predicting potential failures before they occur.

- Advancements in Fuel Injection Technologies: The market has seen a shift towards electrically controlled injection systems, replacing traditional mechanical ones. These systems offer superior precision and adaptability, crucial for meeting stringent emission regulations and fuel economy targets.

- Growth in Common Rail Technology Adoption: Common rail systems, known for precise control of fuel injection timing and pressure, accounted for over 45% of the diesel fuel injection system market share in 2024. Their widespread adoption across various vehicle types underscores their effectiveness in improving fuel efficiency and engine performance.

These trends reflect a concerted effort within the industry to enhance maintenance practices through technological innovation, leading to increased awareness and implementation of more efficient and reliable diesel engine fuel systems.

Frequently Asked Questions on Diesel Engine Maintenance

1. How often should I replace the fuel filters in my diesel engine?

It’s recommended to replace fuel filters every 10,000 to 15,000 miles. Regular replacement ensures clean fuel flow, preventing contaminants from reaching the engine and causing performance issues. [A1 Diesel]

2. What are the signs of a failing fuel lift pump?

Indicators of a failing lift pump include hard starting, engine hesitation, unusual noises from the pump, and decreased engine performance. Addressing these symptoms promptly can prevent more severe engine damage. [Kemsoracing]

3. How can I prevent water contamination in my diesel fuel system?

To minimize water contamination:

- Regularly drain the water separator, especially in humid or cold climates.

- Keep the fuel tank as full as possible to reduce condensation.

- Use high-quality diesel fuel from reputable sources.

These practices help prevent microbial growth and corrosion within the fuel system. [Practical Sailor]

4. What maintenance practices can extend the life of my diesel engine’s lift pump?

To prolong lift pump life:

- Replace fuel filters at manufacturer-recommended intervals.

- Use high-quality diesel fuel from reputable stations.

- Monitor fuel pressure to detect early signs of pump issues.

- Address any warning signs, such as hard starting or unusual noises, promptly.

These steps help maintain the lift pump’s functionality and prevent premature failure. [Kemsoracing]

5. How does microbial contamination affect diesel fuel systems, and how can it be prevented?

Microbial contamination, often referred to as “diesel bug,” occurs when bacteria and fungi grow in the fuel, especially in the presence of water. This can lead to clogged filters, corrosion, and engine performance issues. To prevent this:

- Regularly inspect and maintain fuel storage tanks.

- Use biocides as preventive measures.

- Keep the fuel system dry and free from water intrusion.

Implementing these practices reduces the risk of microbial growth and associated problems. [Wikipedia]

Regular maintenance and prompt attention to any issues are key to ensuring the reliability and efficiency of your diesel engine’s fuel system and lift pump.

Frequently Asked Questions on Diesel Engine Maintenance

1. How often should I replace the fuel filters in my diesel engine?

It’s recommended to replace fuel filters every 10,000 to 15,000 miles. Regular replacement ensures clean fuel flow, preventing contaminants from reaching the engine and causing performance issues. [A1 Diesel]

2. What are the signs of a failing fuel lift pump?

Indicators of a failing lift pump include hard starting, engine hesitation, unusual noises from the pump, and decreased engine performance. Addressing these symptoms promptly can prevent more severe engine damage. [Kemsoracing]

3. How can I prevent water contamination in my diesel fuel system?

To minimize water contamination:

- Regularly drain the water separator, especially in humid or cold climates.

- Keep the fuel tank as full as possible to reduce condensation.

- Use high-quality diesel fuel from reputable sources.

These practices help prevent microbial growth and corrosion within the fuel system. [Practical Sailor]

4. What maintenance practices can extend the life of my diesel engine’s lift pump?

To prolong lift pump life:

- Replace fuel filters at manufacturer-recommended intervals.

- Use high-quality diesel fuel from reputable stations.

- Monitor fuel pressure to detect early signs of pump issues.

- Address any warning signs, such as hard starting or unusual noises, promptly.

These steps help maintain the lift pump’s functionality and prevent premature failure. [Kemsoracing]

5. How does microbial contamination affect diesel fuel systems, and how can it be prevented?

Microbial contamination, often referred to as “diesel bug,” occurs when bacteria and fungi grow in the fuel, especially in the presence of water. This can lead to clogged filters, corrosion, and engine performance issues. To prevent this:

- Regularly inspect and maintain fuel storage tanks.

- Use biocides as preventive measures.

- Keep the fuel system dry and free from water intrusion.

Implementing these practices reduces the risk of microbial growth and associated problems. [Wikipedia]

User Adoption Trends in Diesel Engine Maintenance Practices

Recent trends in diesel engine maintenance practices, particularly concerning lift pumps and fuel systems, indicate a growing emphasis on advanced technologies and predictive maintenance strategies. The following developments have been observed:

- Integration of Electronic Control Units (ECUs): By 2024, over 60% of new diesel fuel pump models incorporated ECUs, enabling real-time performance monitoring via CAN bus systems. This advancement facilitates proactive maintenance and enhances fuel system reliability.

- Adoption of Predictive Maintenance Protocols: The implementation of AI-powered diagnostics in injection pumps allows for the analysis of fuel flow patterns and pressure anomalies in real time. This approach minimizes downtime, optimizes fuel economy, and reduces long-term operational costs by predicting potential failures before they occur.

- Advancements in Fuel Injection Technologies: The market has seen a shift towards electrically controlled injection systems, replacing traditional mechanical ones. These systems offer superior precision and adaptability, crucial for meeting stringent emission regulations and fuel economy targets.

- Growth in Common Rail Technology Adoption: Common rail systems, known for precise control of fuel injection timing and pressure, accounted for over 45% of the diesel fuel injection system market share in 2024. Their widespread adoption across various vehicle types underscores their effectiveness in improving fuel efficiency and engine performance.

These trends reflect a concerted effort within the industry to enhance maintenance practices through technological innovation, leading to increased awareness and implementation of more efficient and reliable diesel engine fuel systems.