Maintaining a vehicle’s brake system is an essential aspect of ensuring your safety on the road. Brake problems diagnosis is a skill that every driver should possess, as even the faintest noises can alert you to underlying issues before they escalate into major repairs. From the dreaded grinding noise of worn-out brake pads to the rhythmic squeaking that might signal a need for lubrication, understanding these sounds can help prolong the life of your brake components.

Shockingly, our driving habits have a significant impact on the longevity of our brakes. For instance, aggressive braking can lead to premature wear, while smooth driving techniques often result in more durable brake systems. Whether you’re just learning about brake maintenance or seeking to refine your knowledge, this blog post will guide you through the critical points of brake system maintenance and the driving habits that can keep you safe and reduce costs in the long run. By honing in on effective brake problems diagnosis, you can ensure that your vehicle remains reliable, and safe to drive, and that your wallet stays intact.

Brake Issues: Understanding Common Problems and Their Symptoms

Brake issues are critical for vehicle safety, and understanding common problems and their symptoms can help in timely maintenance. Below are some prevalent brake problems, their associated noises, possible causes, and implications:

1. Squeaking or Squealing Noises:

- Possible Causes:

- Moisture on Brake Pads: Overnight condensation or exposure to rain can cause a thin layer of rust on the brake rotors, leading to squeaking when brakes are first applied. This noise typically disappears after a few brake applications. Source

- Worn Brake Pads: Brake pads have wear indicators—small metal tabs that produce a high-pitched squeal when the pads are worn down, signaling the need for replacement. Source

- Low-Quality Brake Pads: Inexpensive or substandard brake pads may be more prone to noise due to inferior materials. Source

- Implications: Ignoring squeaking noises can lead to further wear and potential damage to brake components, increasing repair costs and compromising braking efficiency.

2. Grinding Noises:

- Possible Causes:

- Completely Worn Brake Pads: When pads wear out entirely, the metal backing plates make direct contact with the rotors, causing a grinding sound. Source

- Debris Between Rotor and Pad: Foreign objects like small stones can get lodged between the rotor and pad, leading to grinding noises.

- Implications: Continued driving with grinding brakes can damage rotors and other components, leading to costly repairs and reduced braking effectiveness.

3. Thumping or Pulsating Noises:

- Possible Causes:

- Warped Rotors: Excessive heat can cause brake rotors to warp, leading to a thumping sensation or pulsation when braking. Source

- Uneven Brake Pad Wear: Pads that wear unevenly can cause vibrations and thumping noises.

- Implications: These symptoms can affect braking performance and vehicle control, especially during emergency stops.

4. Clicking Noises:

- Possible Causes:

- Loose Brake Components: Brake pads that are not securely mounted can move, causing clicking sounds during braking. Source

- Worn Anti-Rattle Clips: These clips prevent pad movement; if they break or wear out, clicking noises can occur.

- Implications: While not immediately dangerous, loose components can lead to uneven pad wear and reduced braking efficiency over time.

5. Rubbing or Gurgling Noises at Low Speeds:

- Possible Causes:

- Contaminated Brake Pads or Rotors: Substances like grease or oil on brake components can cause unusual noises.

- Glazed Brake Pads: Overheating can harden the pad surface, leading to noises during low-speed braking.

- Implications: These conditions can reduce braking effectiveness and should be addressed promptly.

General Recommendations:

- Regular Inspections: Have your brakes inspected at least every six months or during routine maintenance to catch issues early.

- Prompt Attention to Noises: Any persistent or unusual brake noise should be evaluated by a qualified mechanic to ensure safety and prevent further damage.

- Quality Parts: Opt for high-quality brake components to ensure longevity and reliable performance.

Addressing brake noises and issues promptly not only ensures your safety but also helps in avoiding more extensive and expensive repairs in the future.

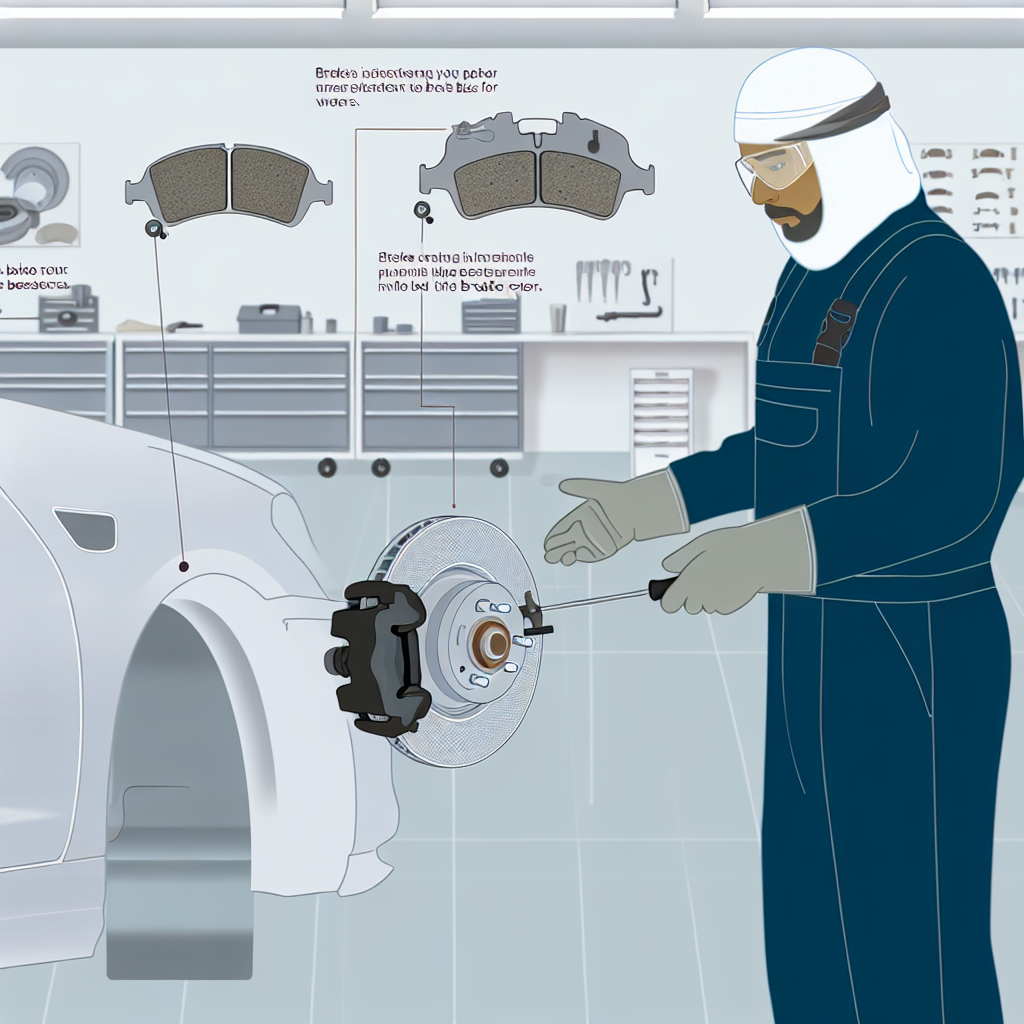

Maintenance Tips for Brake Systems

Maintaining your brake system is crucial for ensuring safety and performance. Here are some practical maintenance tips to help you keep your brakes in top condition:

-

Regular Inspections:

Schedule brake inspections at least every six months or during routine maintenance. A qualified mechanic should check the brake pads, rotors, and fluid levels. Early detection of issues can save you from more extensive repairs and enhance your safety on the road. -

Listen to Your Brakes:

Pay attention to any unusual noises. Squeaking or squealing often indicates worn brake pads or moisture on the rotors. If grinding noises occur, it’s a sign that the pads are completely worn, and metal is grinding against metal, which can damage rotors and increase repair costs. -

Change Brake Fluid Periodically:

Brake fluid can absorb moisture over time, which can lead to decreased braking efficiency. It’s advisable to replace the brake fluid according to your vehicle manufacturer’s recommendations, typically every two years. -

Look for Warning Signs:

Keep an eye on warning lights on your dashboard. If your brake warning light illuminates, have the system checked as soon as possible. Also, be aware of any sensations like pulsating or grabbing when you apply the brakes, as this may indicate rotor issues. -

Replace Worn Components Promptly:

If your mechanic informs you that brake pads or any other components are worn out, replace them immediately. Delaying replacements can lead to more significant problems and increased repair costs down the line. -

Opt for Quality Parts:

When replacing brake components, use high-quality parts. Cheap or substandard parts may compromise braking efficiency and longevity. -

Monitor Your Driving Habits:

Adopting smoother driving habits can prolong the life of your brake components. Gradual stopping instead of sudden halting reduces wear and tear on the brake system. -

Keep Brake System Clean:

Ensure that your brake components are free of debris and contaminants. Frequent cleaning can prevent premature wear and ensure optimal performance. -

Check Brake Lines for Leaks:

Routine checks of your brake lines for leaks or wear will help maintain system integrity. Any signs of leaking brake fluid should be addressed immediately by a professional.

By following these tips and keeping a vigilant eye on your brake system, you can avert issues before they escalate and ensure safer driving experiences. Regular maintenance is key to the longevity of your brake components and the overall safety of your vehicle.

Driving Habits Affecting Brake Life

Mindful driving habits can significantly extend the longevity of your vehicle’s braking system. Techniques such as gradual braking and engine braking not only improve safety but also conserve wear on your brakes, leading to longer-lasting performance.

Gradual Braking

Gradual braking involves the practice of smoothly reducing speed rather than making sudden stops. This technique drastically reduces the amount of heat generated during braking, which is a significant contributor to brake wear. For instance, studies show that by anticipating stops and decelerating gently, drivers can minimize the stress placed on brake pads and rotors. Not only does this reduce how quickly these components wear out, but it can also improve fuel efficiency and overall driving safety. According to research from VarSani Brake Linings, smooth braking is a key factor in extending brake life, showcasing its importance in vehicle maintenance.

Engine Braking

Engine braking is another effective technique that can enhance brake longevity. By downshifting to lower gears, drivers can utilize the engine’s natural resistance to slow the vehicle down, which decreases reliance on the brake pedal. This is especially valuable when driving downhill, as it helps to maintain control and reduces the likelihood of brake overheating, which can lead to failure. A blog from Springs Auto emphasizes that reducing reliance on the brakes through engine braking can significantly prolong the life of brake components.

Additional Tips

In addition to these techniques, other practices such as avoiding overloading your vehicle and maintaining safe following distances can also prevent premature brake wear. Overloading the vehicle increases the demand on brakes, leading to faster wear, while keeping a safe distance from other vehicles allows for smoother deceleration, reducing strain on the system.

By adopting these mindful driving habits, drivers not only contribute to their own safety on the road but also play a crucial role in extending the lifespan of their vehicle’s braking system. Integrating gradual and engine braking into your driving style can lead to cost savings in maintenance and improve the overall performance and safety of your vehicle.

| Brake Noise Type | Potential Causes | Recommended Actions |

|---|---|---|

| Squeaking/Squealing |

|

|

| Grinding |

|

|

| Thumping/Pulsating |

|

|

| Clicking |

|

|

| Rubbing/Gurgling |

|

|

In conclusion, brake maintenance is both crucial and often overlooked, yet it plays a vital role in ensuring vehicle safety and performance. As discussed, different noises from your brake system can provide important clues about potential issues, from worn pads to more serious complications.

Additionally, adopting mindful driving habits, such as gradual braking and utilizing engine braking, can significantly enhance the lifespan of your brakes, saving you money on repairs and providing safer driving experiences. Therefore, it is imperative for all drivers to remain vigilant about their brake systems. Regular inspections and prompt attention to any unusual noises can catch problems early and prevent costly repairs down the line.

We encourage you to routinely check your brakes and seek professional assistance when necessary—your safety on the road is well worth the effort!

User Adoption Data for Brake Maintenance Habits

Understanding user adoption data regarding brake maintenance habits is crucial for promoting better vehicle safety and longevity. Here are some key insights:

Brake Maintenance Delays and Neglect

- According to a 2021 survey by Utires, approximately 25.9% of car owners admitted to delaying brake repairs for a month or longer. Reasons cited included being too busy (54.3%) and financial constraints (52.2%). This highlights a significant concern, as postponing brake maintenance can lead to serious safety issues.

- A 2011 poll conducted by Consumer Reports found that 40% of drivers typically delay necessary automotive maintenance, including brake repairs. Such delays can compromise vehicle safety and prolong existing issues that would have been better addressed sooner.

Brake-Related Complaints and Violations

- In the first half of 2023, the California Bureau of Automotive Repair reported that 16% of all consumer complaints pertained to general repair and maintenance issues, including brakes. This statistic reflects a trend of negligence in maintaining critical vehicle components.

- The 2024 North American Brake Safety Week revealed that 12.8% of inspected commercial motor vehicles were taken out of service due to brake-related violations. This suggests broader maintenance deficiencies within the fleet of vehicles, emphasizing the need for rigorous adherence to brake maintenance protocols.

DIY Brake Maintenance Trends

- A 2025 YouGov survey indicated that 18% of Chevrolet owners and 16% of drivers aged 35-54 are actively involved in performing their own brake maintenance. This behavior indicates a proactive approach by a portion of vehicle owners, suggesting that there is a segment that values hands-on involvement in upkeep and care of their vehicles, including brake systems.

Conclusion

These statistics demonstrate a concerning trend in brake maintenance habits among drivers, highlighting an urgent need to encourage better practices and more consistent adherence to brake inspections and repairs. Without increased awareness and engagement in proper brake maintenance, safety risks can escalate, underscoring the importance of proactive measures in vehicle care.

The Serious Consequences of Neglecting Brake Maintenance

Neglecting brake maintenance can lead to catastrophic accidents, severe emotional trauma, and significant practical consequences. Here are some real-life examples illustrating these risks:

-

Schoharie Limousine Crash (2018):

- Incident: On October 6, 2018, a stretch limousine in Schoharie, New York, experienced brake system failure due to inadequate maintenance. [Wikipedia]

- Consequences: The crash resulted in the deaths of all 18 occupants and two pedestrians, totaling 20 fatalities.

- Emotional Impact: The tragedy deeply affected the victims’ families and the local community, leading to widespread grief and calls for stricter vehicle safety regulations.

-

Eastman Bus Crash (1978):

- Incident: On August 4, 1978, a chartered bus in Eastman, Quebec, suffered brake failure while descending a steep hill, plunging into Lac d’Argent. [Wikipedia]

- Consequences: The accident claimed 40 lives, making it one of Canada’s deadliest road traffic incidents.

- Emotional Impact: The loss of life, especially among vulnerable individuals, left a lasting emotional scar on the community and highlighted the critical importance of vehicle maintenance.

-

Lac-Mégantic Rail Disaster (2013):

- Incident: On July 6, 2013, an unattended freight train carrying crude oil derailed in Lac-Mégantic, Quebec, due to insufficiently set hand brakes and poor maintenance. [Wikipedia]

- Consequences: The derailment led to explosions and fires, resulting in 47 fatalities and the destruction of over 30 buildings.

- Emotional Impact: The disaster devastated the town, causing profound grief and leading to discussions on railway safety and maintenance practices.

Practical Consequences of Neglecting Brake Maintenance:

- Complete Brake Failure: Ignoring brake issues can lead to total brake failure, resulting in accidents or unsafe driving conditions. [Pugh’s Tire Service]

- Increased Repair Costs: Neglected brake pads can wear down rotors, doubling repair expenses. [Pugh’s Tire Service]

- Tire Degradation: Worn brakes force tires to work harder, leading to uneven wear and reduced lifespan. [Advantage Auto Greer]

- Legal and Financial Liabilities: Faulty brakes can cause accidents, exposing individuals to legal repercussions and financial burdens. [Pugh’s Tire Service]

These examples underscore the critical importance of regular brake maintenance to ensure vehicle safety, prevent tragic accidents, and avoid emotional and practical hardships.