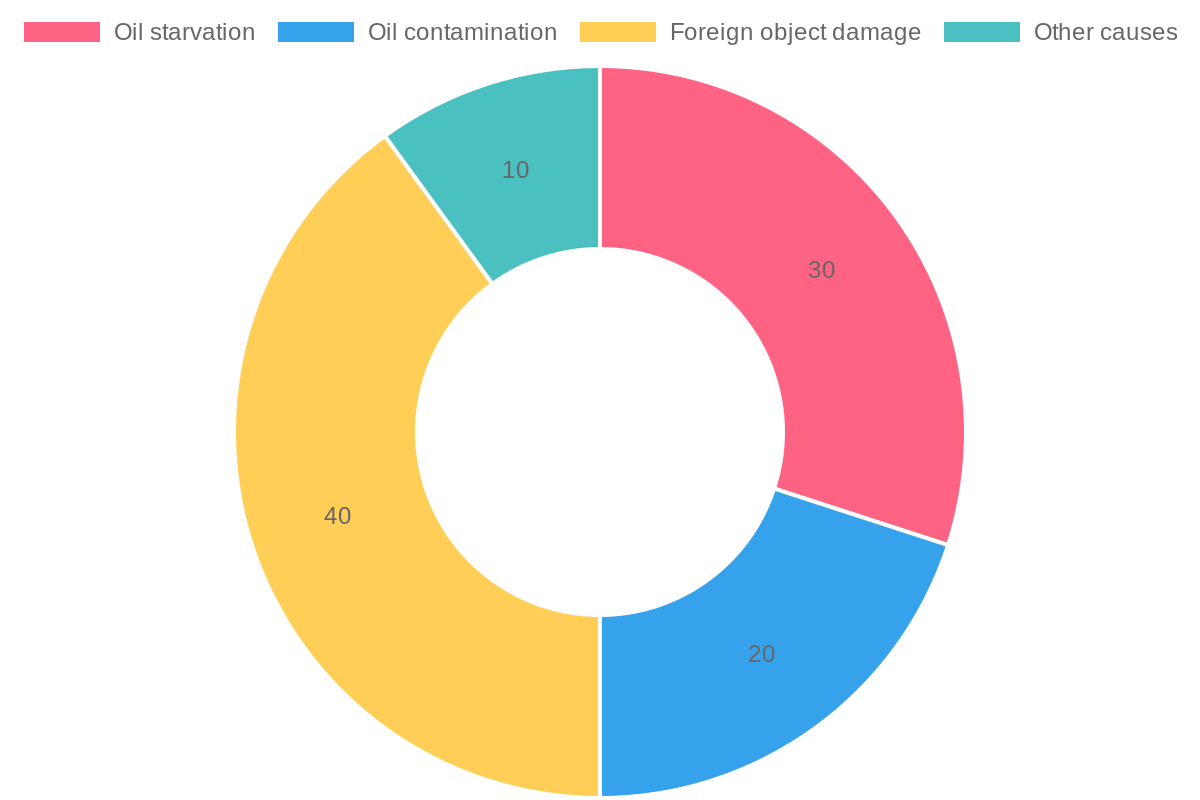

In the fast-paced world of automotive performance, the turbocharger stands as a marvel of engineering, spinning at astonishing speeds of up to 150,000 RPM. It plays a crucial role in enhancing engine power and efficiency, but this powerful component requires vigilant care to prevent premature failure. Have you ever considered the consequences of neglecting your turbocharger’s maintenance? Over 90% of turbocharger failures are attributed to oil starvation or contaminated lubricants, leading to potentially devastating repairs that can drain your wallet. Without proper attention, what could be a powerful ally in your vehicle’s performance can quickly turn into a costly liability.

Understanding the urgency of turbocharger maintenance is essential not just for car enthusiasts but for anyone who wants to ensure their vehicle runs at its best for years to come. Let’s explore the vital steps you can take to safeguard this critical component and maintain the thrill of driving that comes with a well-functioning turbocharger.

Preventing turbocharger failure is a vital aspect of maintaining vehicle performance and longevity. A turbocharger that functions optimally is essential for enhancing engine performance, providing improved acceleration, and increasing fuel efficiency. When properly maintained, a turbocharger can significantly enhance the driving experience, making each ride more enjoyable and responsive. However, neglecting maintenance can lead to grim consequences, including failure and costly repairs.

One of the most compelling reasons to focus on maintaining the turbocharger is the significant costs associated with repair or replacement. Turbocharger failures can lead to engine damage, which is not only expensive to fix but can also result in extended periods of vehicle downtime. Preventative measures such as regular oil changes, inspections, and timely address of warning signs are far less costly than the alternative of reactive repairs. A minor investment in routine maintenance can save vehicle owners substantial amounts in the long run, effectively making prevention the smart choice.

Moreover, consistent care for turbochargers extends the vehicle’s longevity. Regular maintenance contributes to the overall health of the engine, ensuring that all components work harmoniously. A well-maintained turbocharger helps prevent issues that could lead to major engine problems, ultimately extending the life of the entire vehicle.

In conclusion, the importance of preventing turbocharger failure cannot be overstated. Enhanced performance, avoidance of major repairs, increased vehicle longevity, and long-term savings are all compelling reasons to prioritize turbocharger maintenance. Vehicle owners who invest in regular check-ups and maintenance routines will reap benefits that far outweigh the costs, ensuring that their vehicles remain reliable and perform at their best for years to come.

Warning Signs of Turbocharger Failure

Recognizing the early warning signs of turbocharger failure is essential for preventing costly repairs and potential engine damage. Here are the common symptoms to watch for:

-

Loss of Power and Poor Acceleration:

A noticeable decrease in acceleration can indicate that the turbocharger is not providing the necessary boost. This can leave drivers feeling an overall loss of power, making the vehicle sluggish.

Source: Drive Heavy Duty Parts -

Excessive Exhaust Smoke:

If you observe an increase in exhaust smoke, particularly blue or gray, this can be a sign that oil is leaking into the exhaust system due to a failing turbocharger. Worn seals inside the turbo may allow oil to enter the combustion chamber.

Source: Rolfs Import -

Unusual Noises:

Listen for high-pitched whining or whistling sounds coming from the engine bay. These noises can indicate worn bearings or damage within the turbocharger, necessitating immediate attention.

Source: Rolfs Import -

Check Engine Light Activation:

A failing turbo can trigger the check engine light due to low boost pressure or intake air temperature faults, indicating issues that require professional diagnostics.

Source: Naperville Truck Center -

Increased Fuel Consumption:

A malfunctioning turbocharger may disrupt the engine’s air-fuel mixture, resulting in higher fuel consumption as the engine works harder to compensate for the lack of boost.

Source: Branch Automotive -

Oil Leaks:

Visible oil leaks around the turbocharger can indicate damaged seals or oil supply lines, which can worsen turbocharger performance and lead to engine damage if not addressed.

Source: AAA Million

In summary, being alert to these symptoms can save vehicle owners from substantial repair costs and ensure long-term vehicle reliability. Regular maintenance, including oil changes and inspections, is key to preventing these issues from escalating.

For a visual overview of the top symptoms of a failing turbocharger, check this video.

Trends in Turbocharger Maintenance Adoption

Recent trends indicate a growing awareness and adoption of turbocharger maintenance practices among vehicle owners, influenced by technological advancements and the rising prevalence of turbocharged engines.

Maintenance Practices and Awareness

Vehicle owners are becoming more proactive in maintaining turbochargers to enhance performance and longevity. For instance, Blue Ridge Auto recommends a structured maintenance schedule:

- Every 5,000 Miles or 6 Months: Change oil and filter using turbo-specific synthetic oil, inspect the intercooler and associated hoses for leaks, check the air filter condition, and examine turbo oil feed and return lines for leaks or restrictions.

- Every 15,000 Miles or 18 Months: Replace the air filter, perform boost pressure testing, clean the mass airflow sensor and throttle body, and inspect the wastegate actuator operation.

- Every 30,000 Miles or 36 Months: Replace all turbocharger-related hoses and gaskets, perform compression testing, clean or replace the intercooler, and check for exhaust leaks affecting turbocharger performance.

Adhering to this schedule can extend turbocharger life by 40-60% compared to vehicles maintained on standard intervals [Blue Ridge Auto].

Technological Advancements in Maintenance

The integration of AI and IoT-enabled sensors into turbocharger systems is facilitating a shift from reactive to predictive maintenance. These technologies monitor variables such as exhaust pressure, bearing temperature, shaft speed, and vibration patterns in real-time, forecasting potential failures before they occur. This approach reduces unplanned downtime, increases vehicle uptime, and minimizes repair costs for both fleet operators and individual users [Verified Market Reports].

Challenges in Maintenance

Despite increased awareness, challenges persist. Approximately 30% of turbocharger failures are attributed to poor maintenance habits, including the use of substandard or incompatible oils and neglecting oil changes. This issue is particularly pronounced in emerging markets, where awareness of proper maintenance is limited [Market Data Forecast].

Evolution Over Time

The adoption of turbochargers has been on the rise, with penetration expected to increase from approximately 47% in 2017 to about 59% by 2022. This growth is driven by the need for cleaner automotive technologies to meet tightening emission norms, as turbochargers enhance engine efficiency by optimizing fuel combustion [Honeywell].

In summary, vehicle owners are increasingly recognizing the importance of regular turbocharger maintenance, supported by technological advancements that facilitate predictive care. However, challenges remain, particularly in ensuring proper maintenance practices to prevent failures.

Chris Kambouris, Founder and MD of TurboDirect SA, advises that “correct, timeous maintenance will prolong the life of your turbocharger,” stressing that neglecting maintenance can lead to premature failure. (TurboDirect)

This quote underscores the importance of addressing turbocharger issues promptly to avoid more serious complications and costly repairs.

| Turbocharger Lifespan | Common Causes of Failure |

|---|---|

| Average Lifespan: Up to 150,000 miles or more | Oil Starvation: Over 90% of failures due to insufficient lubrication. |

| High RPM Tolerance: Can spin between 80,000 to 150,000 RPM; some high-performance models reach 250,000 RPM | Contaminated Lubricants: Uses of non-standard oils or failures in oil change routines. |

| Maintenance Impact: Regular check-ups can extend lifespan significantly | Worn Seals: Can lead to oil leaks and excessive smoke. |

| Failure Rates: Most failures occur within the first years if not maintained properly | Cooling System Issues: Poor cooling can damage turbo components. |

In conclusion, turbocharger maintenance is paramount for anyone seeking to maximize vehicle performance and longevity. With the potential lifespan of a turbocharger reaching up to 150,000 miles, regular care can significantly reduce the likelihood of premature failure. This article has highlighted key factors that contribute to turbocharger health, including the need for timely oil changes, awareness of contamination, and attention to warning signs such as power loss, excessive exhaust smoke, and abnormal noises.

Vigilance in maintenance practices and recognizing early warning signs are essential steps in safeguarding your vehicle against costly repairs and performance drops. Over 90% of turbocharger failures can be traced back to avoidable issues, emphasizing the need for well-informed vehicle owners to adopt proactive maintenance routines. This includes adhering to recommended servicing schedules, monitoring oil quality, and quickly addressing any irregularities that arise.

Furthermore, trends indicate a growing awareness among motorists regarding these practices, bolstered by advancements in technology that enable better monitoring of turbocharger performance. As more drivers appreciate the value of routine inspections and predictive maintenance, they can enjoy enhanced driving experiences and peace of mind.

Encouragingly, investing in regular maintenance not only extends the life of the turbocharger but also contributes to the overall health of the engine, ensuring all components operate harmoniously. Now is the time for vehicle owners to take action, prioritizing turbocharger care to enjoy the benefits of a responsive, powerful, and reliable vehicle for many years to come. Don’t wait for warning signs—stay ahead of potential failures by adopting a robust maintenance strategy today!

Maintenance Tips for Turbochargers

To ensure the health and longevity of your turbocharger, consider implementing the following practical maintenance tips:

- Regular Oil Changes:

- Change the engine oil and filter according to the manufacturer’s recommended schedule—typically every 5,000 to 7,500 miles.

- Using high-quality synthetic oil designed for turbocharged engines will help reduce wear and tear.

- Check Oil Quality:

- Regularly inspect the oil for contamination.

- Look for dark or gritty oil, which indicates it’s time for a change to prevent lubrication issues that can lead to turbocharger failure.

- Monitor Coolant Levels:

- Ensure that the coolant levels are within the recommended range.

- Proper cooling is essential for preventing turbo overheating, which can cause serious damage.

- Inspect Intercooler and Hoses:

- Periodically check the intercooler for damage, leaks, and debris accumulation.

- Inspect all hoses connected to the turbocharger for cracks or loose connections.

- Warm Up Before Driving:

- Allow your engine to warm up for a few minutes before driving, particularly in cold weather.

- This helps ensure that the oil circulates properly through the turbocharger, reducing oil starvation risk.

- Avoid Idle for Extended Periods:

- Avoid idling for long periods, especially after extended highway driving.

- Letting the engine idle allows the turbo to cool down gradually, preventing heat damage.

- Use Engine Cut-Off:

- If you need to stop after a hurry, turn off the engine only after allowing the turbo to cool down for a few minutes.

- This ensures the bearings within the turbo do not suffer from thermal stress.

- Listen for Unusual Sounds:

- Pay attention to any strange noises, such as whining or decline in performance.

- These signs may indicate that the turbocharger is under stress or failing and should be checked immediately.

- Check for Exhaust Smoke:

- If you see blue or gray exhaust smoke, it’s a sign that oil is leaking into the combustion chamber.

- This requires immediate attention to prevent extensive engine damage.

- Consult a Professional:

- Regularly consult with a certified mechanic experienced with turbocharger systems.

- They can perform detailed inspections and services beyond typical DIY maintenance.

By following these maintenance tips, you can significantly extend the life of your turbocharger and ensure that it continues to perform as intended. Proactive care will lead to a more enjoyable driving experience and ultimately save on costly repairs down the line.

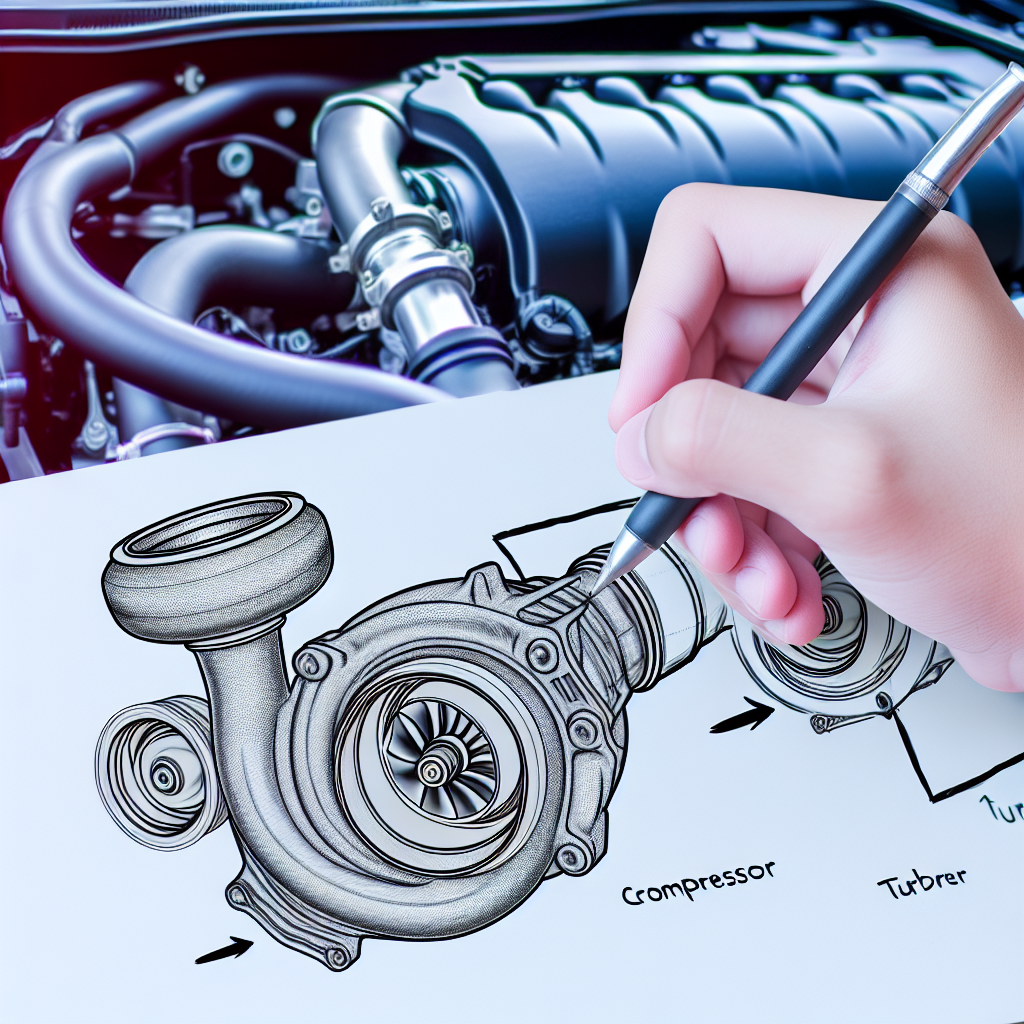

An illustration showing how a turbocharger operates within a car engine, highlighting key components like the turbine and compressor, and depicting airflow for better understanding.

Engaging Statistics on Turbocharger Failures

Key Statistics

- Proper maintenance is crucial for turbocharger longevity, typically extending their lifespan to between 100,000 to 150,000 miles.

- Over 70% of turbocharger bearing failures are attributed to poor oil quality or oil starvation, highlighting the importance of regular oil changes with high-quality synthetic oil [source].

- It is recommended that turbocharged engines undergo oil changes every 5,000 miles using high-quality, turbo-specific synthetic oil to maintain optimal performance [source].

- Regular inspection and maintenance of the air filter are critical as contaminants can damage the turbo system. Frequent changes are particularly advised in dusty or harsh driving conditions [source].

- To ensure longevity, it’s essential to allow the engine to warm up before driving and cool down after, reducing unnecessary wear and tear on the turbocharger [source].

- Engaging with professional servicing regularly can identify potential issues that can save vehicle owners costs and extend their turbocharger’s lifespan [source].

Conclusion

These statistics underline the importance of diligent turbocharger maintenance, emphasizing how proactive practices can significantly reduce the risk of failures and extend the component’s life, ensuring that your vehicle remains responsive and powerful for years to come.

In conclusion, turbocharger maintenance is paramount for anyone seeking to maximize vehicle performance and longevity. With the potential lifespan of a turbocharger reaching up to 150,000 miles, regular care can significantly reduce the likelihood of premature failure. This article has highlighted key factors that contribute to turbocharger health, including the need for timely oil changes, awareness of contamination, and attention to warning signs such as power loss, excessive exhaust smoke, and abnormal noises.

Vigilance in maintenance practices and recognizing early warning signs are essential steps in safeguarding your vehicle against costly repairs and performance drops. Over 90% of turbocharger failures can be traced back to avoidable issues, emphasizing the need for well-informed vehicle owners to adopt proactive maintenance routines. This includes adhering to recommended servicing schedules, monitoring oil quality, and quickly addressing any irregularities that arise.

Furthermore, trends indicate a growing awareness among motorists regarding these practices, bolstered by advancements in technology that enable better monitoring of turbocharger performance. As more drivers appreciate the value of routine inspections and predictive maintenance, they can enjoy enhanced driving experiences and peace of mind.

Encouragingly, investing in regular maintenance not only extends the life of the turbocharger but also contributes to the overall health of the engine, ensuring all components operate harmoniously. Now is the time for vehicle owners to take action, prioritizing turbocharger care to enjoy the benefits of a responsive, powerful, and reliable vehicle for many years to come. Don’t wait for warning signs—stay ahead of potential failures by adopting a robust maintenance strategy today!

Warning Signs of Turbocharger Failure

Recognizing the early warning signs of turbocharger failure is essential for preventing costly repairs and potential engine damage. Here are the common symptoms to watch for:

- Loss of Power and Poor Acceleration:

A noticeable decrease in acceleration can indicate that the turbocharger is not providing the necessary boost. This can leave drivers feeling an overall loss of power, making the vehicle sluggish.

*Source: Drive Heavy Duty Parts* - Excessive Exhaust Smoke:

If you observe an increase in exhaust smoke, particularly blue or gray, this can be a sign that oil is leaking into the exhaust system due to a failing turbocharger. Worn seals inside the turbo may allow oil to enter the combustion chamber.

*Source: Rolfs Import* - Unusual Noises:

Listen for high-pitched whining or whistling sounds coming from the engine bay. These noises can indicate worn bearings or damage within the turbocharger, necessitating immediate attention.

*Source: Rolfs Import* - Check Engine Light Activation:

A failing turbo can trigger the check engine light due to low boost pressure or intake air temperature faults, indicating issues that require professional diagnostics.

*Source: Naperville Truck Center* - Increased Fuel Consumption:

A malfunctioning turbocharger may disrupt the engine’s air-fuel mixture, resulting in higher fuel consumption as the engine works harder to compensate for the lack of boost.

*Source: Branch Automotive* - Oil Leaks:

Visible oil leaks around the turbocharger can indicate damaged seals or oil supply lines, which can worsen turbocharger performance and lead to engine damage if not addressed.

*Source: AAA Million*

In summary, being alert to these symptoms can save vehicle owners from substantial repair costs and ensure long-term vehicle reliability. Regular maintenance, including oil changes and inspections, is key to preventing these issues from escalating.

A case study illustrates the critical importance of recognizing these signs early:

Case Study: Turbocharger Failure Due to Oil Starvation

Background:

A BMW vehicle experienced a sudden loss of power and emitted excessive exhaust smoke. Upon inspection, technicians at Atlantic Motorcar Center identified a failed turbocharger as the culprit. (atlanticmotorcar.com)

Cause:

The primary cause of the turbocharger failure was oil starvation. This condition arose due to a blocked oil supply line, preventing adequate lubrication of the turbocharger’s bearings. Oil starvation can result from several factors, including:

- Blocked or leaking oil supply lines: Accumulation of sludge or debris can obstruct oil flow.

- Infrequent oil changes: Old or degraded oil can lead to sludge buildup.

- Use of incorrect oil type: Non-recommended oils may not provide proper lubrication.

These issues can lead to increased friction, overheating, and eventual failure of the turbocharger. (atlanticmotorcar.com)

Consequences:

- Reduced engine power: The vehicle struggled to accelerate and maintain speed.

- Excessive exhaust smoke: Burning oil produced visible smoke from the exhaust.

- Potential engine damage: Continued operation could have caused further harm to engine components.

Lessons Learned:

- Regular Maintenance: Adhering to the manufacturer’s recommended maintenance schedule is vital. Regular oil and filter changes help prevent sludge buildup and ensure proper lubrication. (atlanticmotorcar.com)

- Use of Correct Oil: Employing the manufacturer-recommended oil type and viscosity ensures optimal lubrication and reduces the risk of blockages.

- Prompt Attention to Warning Signs: Early symptoms like loss of power, unusual noises, or increased exhaust smoke should be promptly addressed to prevent further damage.

This case underscores the importance of regular maintenance and vigilance in recognizing early warning signs to prevent turbocharger failures and maintain engine performance.

Trends in Turbocharger Maintenance Adoption

Recent trends indicate a growing awareness and adoption of turbocharger maintenance practices among vehicle owners, influenced by technological advancements and the rising prevalence of turbocharged engines.

Maintenance Practices and Awareness

Vehicle owners are becoming more proactive in maintaining turbochargers to enhance performance and longevity. For instance, Blue Ridge Auto recommends a structured maintenance schedule:

- Every 5,000 Miles or 6 Months: Change oil and filter using turbo-specific synthetic oil, inspect the intercooler and associated hoses for leaks, check the air filter condition, and examine turbo oil feed and return lines for leaks or restrictions.

- Every 15,000 Miles or 18 Months: Replace the air filter, perform boost pressure testing, clean the mass airflow sensor and throttle body, and inspect the wastegate actuator operation.

- Every 30,000 Miles or 36 Months: Replace all turbocharger-related hoses and gaskets, perform compression testing, clean or replace the intercooler, and check for exhaust leaks affecting turbocharger performance.

Adhering to this schedule can extend turbocharger life by 40-60% compared to vehicles maintained on standard intervals (Blue Ridge Auto).

Technological Advancements in Maintenance

The integration of AI and IoT-enabled sensors into turbocharger systems is facilitating a shift from reactive to predictive maintenance. These technologies monitor variables such as exhaust pressure, bearing temperature, shaft speed, and vibration patterns in real-time, forecasting potential failures before they occur. This approach reduces unplanned downtime, increases vehicle uptime, and minimizes repair costs for both fleet operators and individual users (Verified Market Reports).

Challenges in Maintenance

Despite increased awareness, challenges persist. Approximately 30% of turbocharger failures are attributed to poor maintenance habits, including the use of substandard or incompatible oils and neglecting oil changes. This issue is particularly pronounced in emerging markets, where awareness of proper maintenance is limited (Market Data Forecast).

Evolution Over Time

The adoption of turbochargers has been on the rise, with penetration expected to increase from approximately 47% in 2017 to about 59% by 2022. This growth is driven by the need for cleaner automotive technologies to meet tightening emission norms, as turbochargers enhance engine efficiency by optimizing fuel combustion (Honeywell).

In summary, vehicle owners are increasingly recognizing the importance of regular turbocharger maintenance, supported by technological advancements that facilitate predictive care. However, challenges remain, particularly in ensuring proper maintenance practices to prevent failures.

This graph illustrates the common causes of turbocharger failure, highlighting the significant impact of oil starvation, oil contamination, and foreign object damage.