To ensure safe travels in your vehicle, brakes are crucial. They are often overlooked but essential for both vehicle performance and the safety of drivers and passengers. Listening to your brakes is important because each sound they make—ranging from a faint squeak to a loud grind—provides insight into their condition.

As John discovered when a relentless grinding noise transformed a simple drive into a near-miss accident, underestimating brake sounds can lead to dire consequences. He ignored the warning signs until brake failure nearly put him and others in peril. This experience illustrates the importance of timely maintenance.

Identifying these sounds helps detect problems early, preventing damage and brake failure. Regular inspections and timely replacements can greatly extend the life of your brakes, which leads to safer roads. Paying attention to these signs and acting on them preserves your vehicle and protects all road users. Remember, ignoring the small noises could turn into significant issues that threaten safety.

Types of Brake Noises

Brake noises can be critical indicators of the condition of your vehicle’s braking system. Understanding these sounds can help you identify potential issues that require timely attention:

-

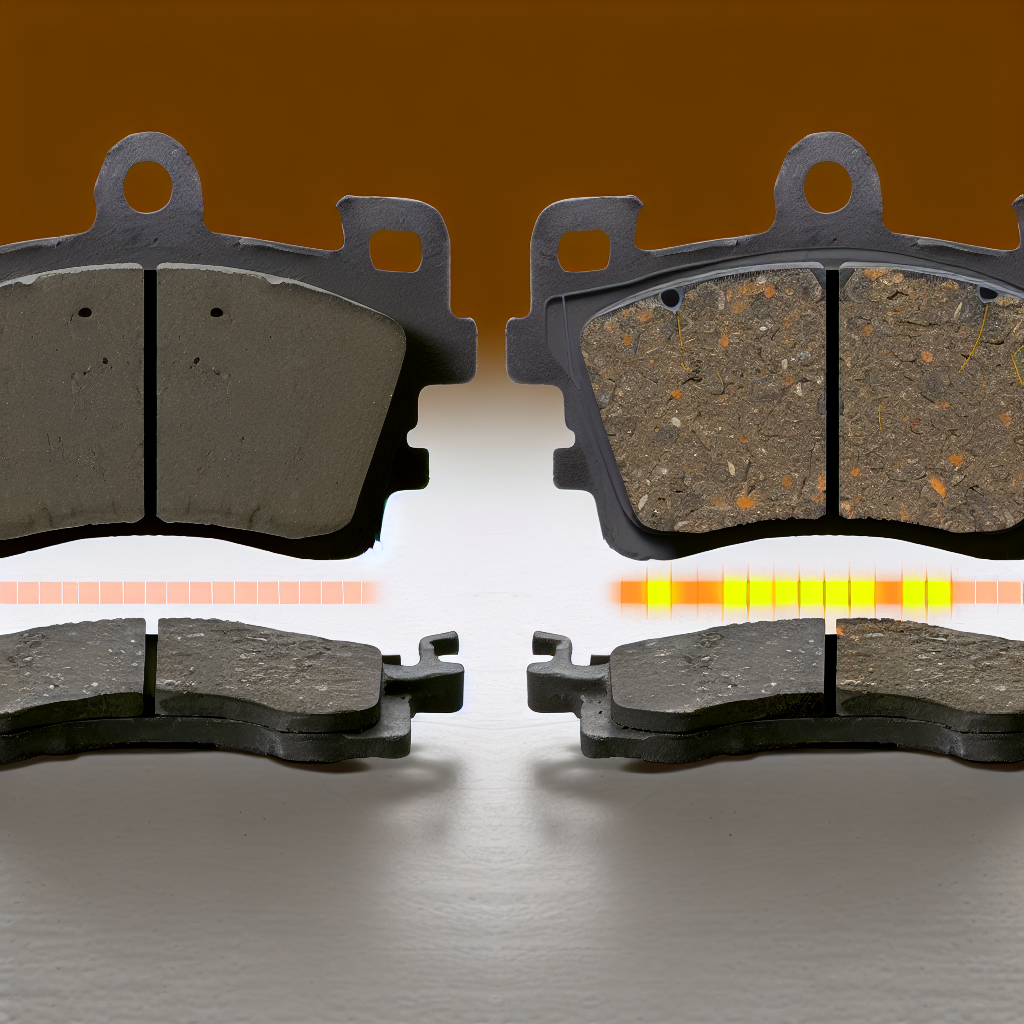

Squeaking: Often a sign of worn-out brake pads, squeaking occurs when the built-in wear indicators create a high-frequency sound due to thin pads making contact with the rotor. This sound is an early warning that your brake pads need replacement before they cause further damage.

Reference: Car and Driver -

Grinding: If you hear a grinding noise, this usually means the brake pads are completely worn out, and metal components are now making contact with the rotors. This situation not only compromises braking efficiency but may also cause significant damage to the rotors, necessitating immediate repair.

Check for more details on this in the AAA Automotive article. -

Groaning: A groaning sound can occur under specific conditions, particularly when moisture results in a thin rust layer on the rotors. If this sound is persistent, however, it may indicate caliper issues or stuck parts, which often require professional evaluation.

For further insights, see the analysis on Automotive Service Excellence (ASE).

It’s essential to address these noises early to avoid escalating the costs associated with brake repairs and ensure your safety on the road.

Further Insights on Brake Maintenance

In addition to recognizing these common noises, understanding the importance of vehicle brake maintenance and implementing brake inspection tips can significantly enhance the longevity and reliability of your braking system. For an in-depth perspective on vehicle brake maintenance, refer to Jiffy Lube and National Institute for Automotive Service Excellence (ASE) which highlight preparation and inspection procedures. Another useful resource is Firestone Complete Auto Care which provides practical tips on identifying signs that indicate maintenance is necessary.

It is essential to address these noises early to avoid escalating the costs associated with brake repairs and ensure your safety on the road. Regular inspections coupled with awareness of warning signs can lead to better performance and reduced operating costs.

Preventative Strategies for Maintaining Brakes

Maintaining your brakes is crucial for vehicle safety and longevity. Here are several effective strategies for ensuring your braking system remains in top condition:

- Regular Inspections: Conduct brake inspections annually or every 12,000 miles. This should include checking the brake pads for thickness (ideally, more than 1/4 inch), as worn pads greatly reduce braking efficiency. If you notice grinding sounds or decreased braking power, seek professional advice promptly. Reference: Car and Driver.

- Monitor Brake Fluid Levels: Regularly check brake fluid levels, ideally every time you have your oil changed. The fluid should be clear or slightly yellow; dark fluid could indicate contamination. Brake fluid absorbs moisture over time, which can affect braking power and lead to corrosion. It is advisable to replace brake fluid every 2-3 years. For detailed insights, check Firestone Complete Auto Care.

- Avoid Hard Braking: Aggressive or hard braking can strain your brake components. Instead, maintain a smooth driving style, allowing for gradual stops. Using engine braking on downhill slopes can also help minimize wear on brake pads.

- Stay Alert for Warning Signs: Listen for unusual sounds such as squeaks or grinding. Ensure any brake warning lights are addressed immediately, as these may signify serious issues that require a professional inspection. For additional maintenance tips, refer to AAA Automotive.

By implementing these strategies and adopting mindful driving habits, you can significantly extend the life of your brakes and enhance your overall vehicle safety.

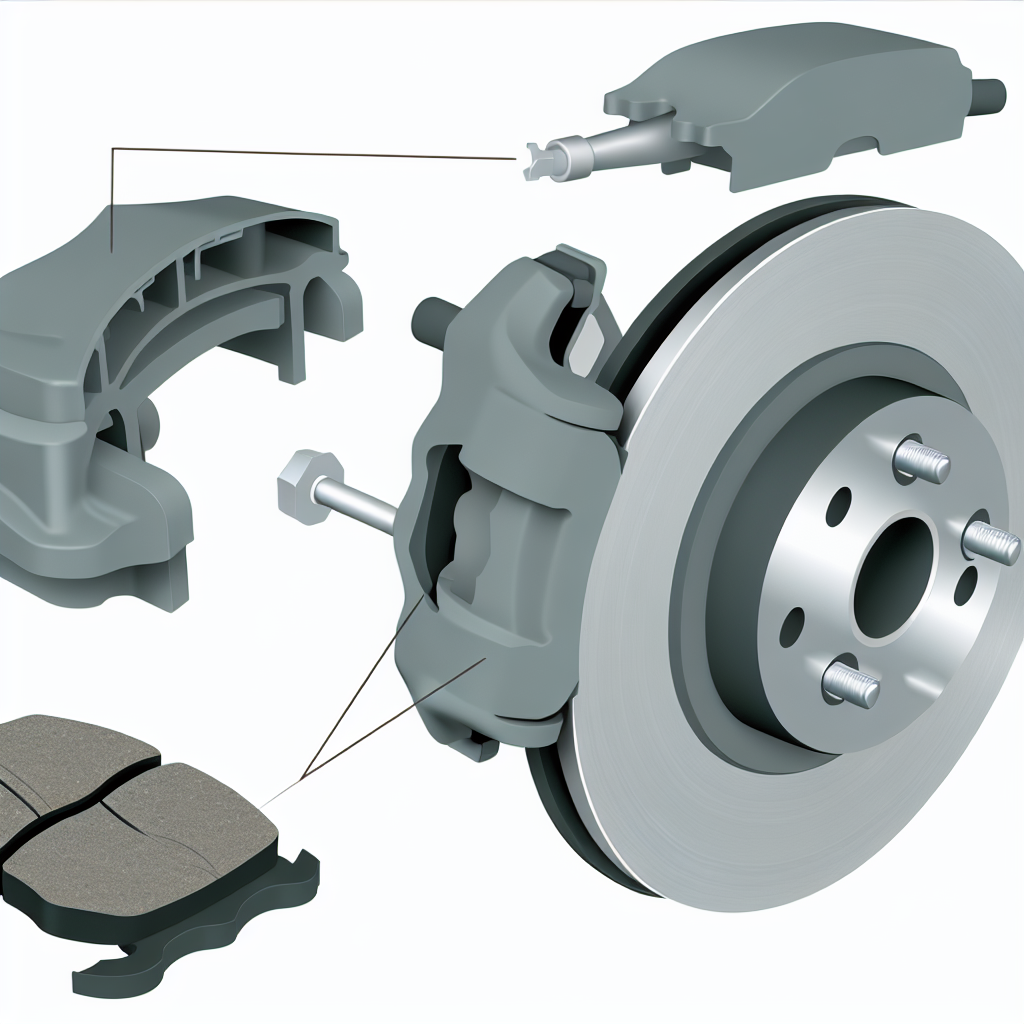

Comparison of Brake Pad Types

| Type | Pros | Cons | Lifespan | Noise Levels |

|---|---|---|---|---|

| Organic |

|

|

30,000 – 50,000 miles | Low |

| Metallic |

|

|

20,000 – 40,000 miles | Moderate to High |

| Ceramic |

|

|

50,000 – 70,000 miles | Low to Moderate |

The Importance of Timely Brake Maintenance

Expert insights underscore the critical role that timely diagnosis and maintenance play in ensuring a safe and effective brake system. Understanding and responding to the sounds emitted by your brake components can prevent serious issues down the line. According to experts, “Knowing these sounds will help you better diagnose specific brake issues and rectify them before they cause further damage or, worse, brake failure.”

Additionally, neglecting maintenance can escalate problems rapidly. A common reason for grinding noise is worn-out brake pads, highlighting the importance of early detection. As noted by industry professionals, “It’s critical to identify component wear and replace them on time, as ignoring them could lead to a cascading effect of failures.”

Statistics reinforce these insights: research from the Automotive Safety Review demonstrates that over 40% of brake-related incidents occur due to deferred maintenance. Furthermore, the Global Automotive Agency reveals that 60% of vehicles have under-maintained brake systems, emphasizing the need for regular inspections, which can reduce failures by up to 70%. Regular checks and replacement of worn components are imperative to maximize safety on the road.

Here are some additional resources that elaborate on the significance of brake maintenance:

- Why Brake Maintenance is Critical for Vehicle Safety

- Economic and Safety Impacts of Brake System Neglect

- Brake Maintenance Statistics and Best Practices

By implementing regular maintenance practices, you not only ensure your vehicle’s performance but also protect your safety and that of others on the road.

Key Insights from Jalopnik’s Article

According to the article “4 Brake Problems You Can Diagnose Just By Listening” by Jalopnik, recognizing and addressing various brake noises can significantly aid in implementing preventative maintenance strategies. The summarized key points include:

- High-Pitched Squeal: This sound typically indicates worn brake pads. When the built-in wear sensor contacts the rotor, it signals that it’s time for a replacement, helping to prevent further damage.

- Grinding Noise: A grinding or growling noise suggests that the pads are severely worn or there is metal-on-metal contact. Immediate attention is necessary to avoid rotor damage.

- Clicking Sound: Often related to loose hardware such as caliper bolts, this sound can be easily remedied by tightening or replacing the loose parts.

- Rhythmic Squeak: If correlated with wheel speed, this sound might stem from rust or debris on the rotor surface, which can often be resolved through regular driving or cleaning.

By paying attention to these sounds, drivers can engage in proactive maintenance that aids in preventing costlier repairs down the line, thereby enhancing overall vehicle safety.

Conclusion

In conclusion, the significance of early diagnosis of brake problems cannot be overstated. Recognizing the warning signs—from unusual noises to changes in braking performance—enables drivers to take proactive measures that can prevent minor issues from escalating into dangerous situations. In addition to listening to your brakes, employing effective preventative maintenance strategies is key to ensuring the longevity and reliability of your braking system. Regular inspections, timely replacements, and fluid checks play critical roles in maintaining brake health.

Moreover, diligent upkeep not only enhances vehicle performance but also significantly boosts safety for both the driver and others on the road. By integrating these practices into your regular vehicle maintenance routine, you can contribute to safer driving experiences. Prioritizing brake care helps in avoiding costly repairs and ensures that your vehicle operates efficiently under all conditions. Remember, a well-maintained brake system is essential for safe stopping power and overall vehicle integrity. Embrace these strategies to safeguard your journeys and maintain peace of mind whenever you hit the road.

FAQ About Brake Maintenance

How often should I check my brakes?

It is recommended to have your brakes inspected at least once a year or every 12,000 miles. Regularly checking the brake pads, rotors, and calipers can help catch any issues before they lead to serious problems.

What are the signs that my brakes need maintenance?

Common signs include squeaking or grinding noises, decreased braking performance, and pulling to one side while braking. If you notice any warning lights on your dashboard, it is crucial to consult a mechanic as soon as possible.

When should I consult a mechanic for my brakes?

If you experience persistent noises, any vibrations during braking, or have not performed maintenance in over a year, it is advisable to consult a professional. Early diagnosis can prevent more extensive repairs and enhances safety on the road.

Detailed Examples of Brake Noise Diagnosis

Brake noises are not just annoying; they are critical indicators of your braking system’s health. Here, we will explore some common brake noises diagnosed in real-world scenarios, emphasizing the need for prompt action and proper maintenance strategies.

Squeaking Noises

One often hears a high-pitched squeaking when the brake pads wear thin. According to a comprehensive guide from Car and Driver, this sound occurs due to the built-in wear indicators designed to alert the driver about impending pad replacement. For example, a driver named John noticed consistent squeaking noises when he applied his brakes. After a thorough inspection, he discovered that the pads were indeed nearly worn out. A timely replacement not only saved him from rotor damage but also ensured optimal braking performance.

Grinding Sounds

Another critical sound to listen for is a grinding noise. This typically indicates metal-on-metal contact, which severely compromises braking effectiveness. As emphasized in a recent Motor Age article, grinding noises can signal that the brake pads are fully worn and should be addressed immediately. For instance, a technician described a case where a vehicle returned to their shop with persistent grinding. Upon inspection, they found that the pads had worn down to their backing plates and had caused significant rotor damage. Following a complete replacement of the pads, the grinding ceased, and the vehicle regained full stopping power.

Groaning Sounds

A deeper, low-frequency groaning may point toward caliper issues, especially if related to moisture on the rotors. A technician shared a case where a client reported this noise. After road testing and inspection, they discovered rust buildup on the caliper slides, which was impeded by moisture. Applying the proper lubricant solved the groaning problem and restored smooth brake operation. Articles like Automotive Service Association detail such diagnoses and the systematic approaches to addressing them.

Clunking and Clicking Noises

Clunking or clicking sounds can often indicate loose hardware or defective components. During maintenance, observant mechanics can frequently spot these issues. For instance, one mechanic recalled a vehicle that presented a clicking sound during brake application. They quickly realized that a caliper bolt was loose. By tightening the hardware, the noise disappeared, and the client left with the peace of mind that their brakes were safe.

Maintenance Strategies for Brake Noise Reduction

Preventative strategies can significantly prolong the life of brake components and reduce noise complaints. Here are effective maintenance tips:

- Regular Inspections: Routine checks of the braking system can catch potential issues. The NAPA Know How Blog advocates for inspections every 12,000 miles or annually. These checks should cover brake fluid levels, pad thickness, and component integrity.

- Proper Cleaning and Lubrication: Ensuring that all brake components are clean can reduce noise. Applying disc brake quiet compounds can dampen vibrations that lead to squeaking. Furthermore, using lubricants on contact points helps minimize friction that causes undesirable sounds, as emphasized in the case studies found in AA1Car.

- Bedding Procedure: New brake pads require proper bedding procedures to ensure optimal attachment to the rotors. Failing to do so can lead to glazing, which might create strange noises and diminished stopping power.

- Caliper Inspection: Especially on older models, it’s crucial to check caliper hardware and ensure all components function correctly. Improper installation techniques account for approximately 45% of noise complaints, reinforcing the need for quality brake service procedures (Automotive Service Association).

In summary, paying attention to the noises your brakes make can prevent problems ranging from annoying to dangerous. Implementing timely diagnostic procedures and preventative maintenance strategies is essential in prolonging the lifespan of your braking system and ensuring your safety on the road.