Proper vehicle maintenance is vital, especially for cars using HFC-134a refrigerant. In this guide, we explore best practices in servicing HFC-134a systems to ensure efficiency and safety. Each chapter delves into key aspects such as the significance of using manufacturer-approved refrigerants, following evacuation procedures, utilizing appropriate refrigerant oils, employing recovery and recycling equipment, and the importance of referencing the official service manual. By understanding these elements, local car owners, used car buyers, and small business fleet operators can maintain optimal air conditioning performance and adhere to environmental regulations.

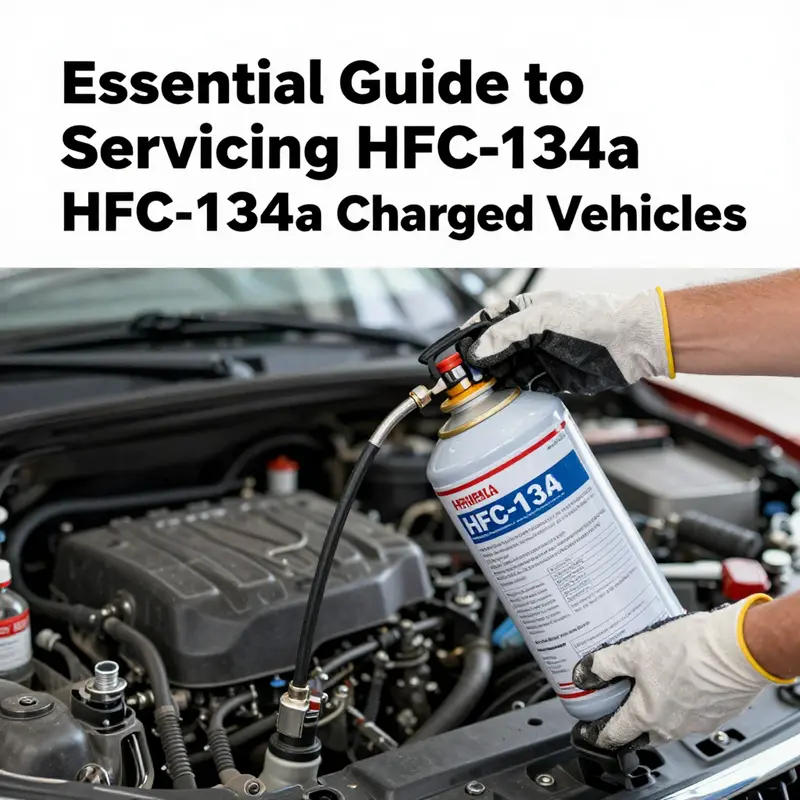

Guarding the Charge: Why Manufacturer-Approved Refrigerants Are Essential When Servicing HFC-134a Vehicles

When servicing a vehicle charged with HFC-134a, the core discipline is straightforward in theory and exacting in practice: use only refrigerants approved by the vehicle’s manufacturer, and follow the procedure precisely as written in the official service guidance. This isn’t a matter of preference but of compatibility, performance, and environmental responsibility. HFC-134a refrigerant formulations are engineered to work with specific lubricants, seals, compressors, and filter-dryers. Introducing an unapproved formula risks a cascade of interactions that can reduce cooling efficiency, compromise components, and create conditions that the original design did not anticipate. The result can be a system that runs hotter, consumes more energy, or, in the worst case, suffers accelerated wear or premature failure of the compressor or o-rings. The consequences extend beyond the vehicle. Any attempt to substitute refrigerants or lubricants without OEM approval can violate environmental and safety regulations, expose technicians to liability, and undermine the integrity of the service history. In short, adherence to manufacturer-approved refrigerants is a practical guarantee of performance and accountability throughout the life of the system.

The practical rationale for this approach rests on the precise chemistry and physics that govern modern automotive air conditioning. HFC-134a systems rely on a particular balance of refrigerant vapor pressures, temperatures, and latent heat transfer behavior. The lubricating oil is chosen to blend with that refrigerant under the system’s range of operating conditions. When a non-approved refrigerant enters the loop, it may alter lubricant solubility, change viscosity characteristics, or interact unfavorably with elastomer seals and gaskets. Over time, these differences can degrade the seal integrity, diminish lubricating performance, and lead to leaks or mechanical stress where the system’s tolerances are already tight. For technicians, this means that even small deviations in refrigerant grade can produce outsized effects on reliability and service life. The prudent path, therefore, is to treat the refrigerant as a critical, design-specific component of the vehicle’s climate control package rather than a generic consumable.

Beyond the immediate mechanical implications, there is a broader regulatory frame that reinforces the decision to use manufacturer-approved refrigerants. The United States Environmental Protection Agency enforces strict handling and disposal rules under Section 609 of the Clean Air Act. Refrigerant recovery and recycling must be performed using certified equipment, and any recovered HFC-134a must be recycled before reuse to ensure purity and prevent contamination. The emphasis is not solely on preventing refrigerant loss; it is about preserving the chemical integrity of the system so that it can be recharged to the exact specifications required by the OEM and maintain compliance with environmental standards. In practice, this means that a service visit should begin with a plan for proper recovery of any existing refrigerant, followed by a careful evacuation of the system to remove air and moisture, and then a controlled recharge with the approved refrigerant grade. A rushed or careless approach risks releasing refrigerant to the atmosphere, compromising air quality, and inviting regulatory scrutiny. Keeping the process aligned with certified equipment and documented procedures is a professional obligation, not merely a best practice.

The conversation around storage and moisture control adds another layer of precision. A critical environmental and functional requirement for HFC-134a systems is the removal of moisture before recharge. Moisture within the system can react with refrigerant and oil to form acids, which attack metal surfaces and degrade seals. This is where the role of a properly functioning storage dryer becomes essential. Standards governance in the industry underscores the need for reliable drying technology to ensure that moisture does not re-enter the circuit during charging or operation. Although the exact specifications are detailed in the relevant national and industry standards, the practical takeaway for technicians is clear: moisture control is not optional. The storage dryer, when properly integrated and maintained, contributes to a stable, long-lasting charge that preserves compressor health and maintains the intended thermodynamic performance of the system. The guidance embedded in such standards reflects years of field experience and laboratory testing, translating complex material science into actionable, real-world requirements.

Equally important is the choice of lubricating oil and its compatibility with the refrigerant. In HFC-134a systems, ester-based POE oils are commonly used because of their good miscibility with 134a at a wide range of temperatures. However, not all vehicles share the same oil type or viscosity, and some configurations are engineered to operate with a particular oil-refrigerant pairing. For this reason, the service manual will specify not only the exact refrigerant grade but also the recommended oil type and the precise oil-to-refrigerant ratio. Substituting one oil for another or mixing oils without a proper flush can leave residues that reduce lubrication efficiency, promote varnish formation, or alter the heat transfer characteristics of the evaporator. The result may be degraded cooling performance or, in the worst case, friction-induced wear that shortens the life of the compressor. This is why the phrase manufacturer-approved refrigerants should be read not as a bureaucratic guardrail but as an engineering directive meant to preserve system integrity.

The procedure that follows is a structured sequence that a technician must respect to bring a charged system back to peak performance while honoring environmental commitments. It begins with verifying the vehicle’s original refrigerant specification and confirming that the service equipment is certified for high-pressure refrigerants. The next step is to evacuate and recover the existing refrigerant, ensuring that the recovered material is processed through a certified recycling circuit and documented in the service report. Only after the system has reached a suitable vacuum level and the moisture content has been reduced should the service proceed to replace any essential dry-state components, such as an inline dryer or filter-dryer if the design calls for it. When new refrigerant is introduced, it must be the exact OEM grade and water-free, with the oil charge adjusted to the specification in the service manual. The procedure should also preserve a detailed record of refrigerant quantities, pressure readings, ambient conditions, and service tooling used. This documentation provides traceability and accountability, two hallmarks of professional practice in the modern repair shop.

In the broader context of maintenance philosophy, this chapter intersects with other chapters in the article by emphasizing the continuity between refrigerant stewardship and ongoing vehicle care. The choice of refrigerant is not isolated from other service decisions. A well-maintained cooling system benefits from consistent oil-service intervals, careful monitoring of compressor load, and disciplined adherence to the vehicle’s maintenance schedule. For readers seeking a complementary perspective on lubrication strategies in vehicle maintenance, a related discussion on oil-change intervals and time versus mileage can offer practical insights. See the article section on optimal oil-change intervals for a broader picture of how lubricant management supports overall system reliability and performance.

As with any specialized repair work, the emphasis remains on consulting the official service manual and relying on OEM guidance for the exact refrigerant grade, oil type, and charge amount. While this chapter highlights the universal principles that govern safe and responsible service, the precise steps can vary by make, model, and year. The integrity of the service hinges on fidelity to those specifics, coupled with a rigorous commitment to environmental stewardship through certified equipment, proper recovery, and meticulous documentation. The goal is not to simplify complex physics into a quick checklist but to embed best practices into every service action, so that each vehicle leaves the shop with a reliable climate-control system and a transparent service record that stands up to inspection and time.

External reference: QC/T 662-2013 – Automotive air-conditioning (HFC-134a) storage dryer. This Chinese national automotive standard, published by the Ministry of Industry and Information Technology, outlines technical requirements for storage dryers in HFC-134a systems, ensuring compatibility and reliability across vehicles. It remains a key reference for manufacturers and service providers worldwide. https://std.samr.gov.cn/gb/

The Quiet Standard: Mastering Evacuation When Servicing HFC-134a Automotive Air Conditioning

When a vehicle is charged with a refrigerant in the HFC-134a family, evacuation is not merely a preparatory step; it is the core practice that protects people, equipment, and the environment. Moisture and air are the hidden adversaries inside any A/C circuit. Left behind, they form acids, promote corrosion, and foster ice formation that can clog expansion valves, degrade lubricants, and compromise the system’s ability to maintain the desired cooling performance. The discipline of proper evacuation starts before the first wrench turns and continues through every stage of the service. It rests on using the right tools, following the manufacturer’s specifications, and maintaining an unwavering commitment to environmental responsibility. In practical terms, this means relying on equipment designed for R-134a, achieving a truly deep vacuum, and ensuring that no refrigerant escapes to the atmosphere during service. It also means recognizing that technicians must be appropriately certified to handle refrigerants, because the integrity of the procedure depends as much on training as on hardware. A thoughtful, standards-driven approach to evacuation not only safeguards the vehicle’s climate control system but also reduces the risk of liability and environmental harm for the shop and the broader community.

The first major pillar is equipment selection. A system designed for HFC-134a must be paired with recovery and recycling machinery that can accurately process this refrigerant. Recovered gas should be captured, measured, and recycled or reclaimed according to local regulations and the equipment’s capabilities. The hoses, ports, and recovery canisters used during evacuation should be in good condition, with no leaks or signs of damage that could undermine the integrity of the process. The vacuum pump and manifold should be suited to R-134a operations, and gauges must display the system’s status with reliable precision. The principle here is straightforward: the integrity of the evacuation rests on the compatibility and reliability of the hardware you put in service with the refrigerant you are reclaiming.

The core of the evacuation procedure is achieving a deep vacuum. In most vehicle applications, the target is a vacuum well below 500 microns. Why so shallow? Because a deep vacuum indicates that moisture, air, and non-condensables have been removed to the greatest extent possible. Moisture in the system can react with the refrigerant and with the oils, forming acids that corrode metal surfaces and degrade seals. Non-condensables, including air and trace gases, raise the system pressure when the refrigerant is reintroduced, reducing the efficiency of recharging and the long-term performance of the compressor. The process typically begins with the entire system isolated, the recovery phase completed to remove the existing refrigerant, and then a dedicated vacuum stage conducted with the engine off and the system sealed from ambient air. The evacuation time varies with the size of the system and its condition, but the standard objective remains constant: a sustained sub-500-micron reading, followed by a verification period to ensure that the vacuum holds under a slight leakage test.

Even as the goal remains the same, the path to achieving it requires discipline. Hold times during deep evacuation are not arbitrary. They allow the vacuum pump to draw out residual gases and moisture that cling to metal surfaces, desiccants, and internal baffles. A practical approach is to bring the system down to the target vacuum and then hold for a period long enough to confirm stability, often through an additional tenths of a micron verification after a brief exposure to a small amount of non-refrigerant gas to test the integrity of connections and seals. The exact hold duration depends on system complexity and the presence of components such as expansion devices, evaporators, and receiver-drier assemblies, but the guiding principle is steadfast: moisture removal takes priority, and measured, patient vacuum is the instrument that makes it possible.

Alongside the vacuum itself, the procedural mindset must also address the imperative to prevent any refrigerant release. Recovered gas should never be vented to the atmosphere. Modern practice relies on closed-loop recovery and recycling to protect the environment and to comply with applicable regulations. This means careful valve operation, disciplined manual control, and continuous monitoring of the recovery process. If a joint or line must be opened for service, the system should be evacuated to the deepest practical vacuum before any disassembly, and the reclosed system should be checked again after reassembly to confirm that no refrigerant remains to be released. These steps are not merely regulatory boxes to check; they are essential safeguards that preserve the quality of the refrigerant and the health of the technician performing the service.

A crucial companion to the technical steps is the professional credentialing that governs who may handle refrigerants. Certification requirements exist precisely because mishandling refrigerants or mixing different refrigerants can create hazards for people and equipment. The practice of evacuation and recharge is most effective when performed by trained professionals who understand the chemistry of R-134a, the behavior of POE lubricants, and the consequences of moisture in the system. In the context of this chapter, the emphasis is on compliance and competence. The proper evacuation is not a negotiation with chance; it is a disciplined, certified procedure that aligns with the highest standards of automotive service.

For technicians seeking practical, field-tested perspective beyond the core steps, there are established guidelines that distill the experience of many shops. These guidelines emphasize the same core messages: use equipment designed for R-134a; achieve the deep vacuum; avoid refrigerant loss; and operate within certification requirements. The guidance provided by industry documents on R-134a evacuation can be accessed in detail through reputable technical resources. If you are looking for a concise reference that outlines circuit evacuation specifics for certain applications, you will find it useful to consult the documented evacuation practices for R-134a systems and to compare them with your vehicle’s service manual. As you work through the procedure, remember that the exact measurements and hold times can vary with system architecture, but the overarching objective remains consistent: a truly dry, atmosphere-free environment that prepares the system for a precise recharge and reliable performance.

To connect this procedural fidelity with practical insight, consider how a maintenance professional frames the workflow. A well-run evacuation begins with a clean workspace, protective equipment, and a verification plan that confirms the absence of moisture before introducing fresh refrigerant. It continues with a controlled recovery, a deep vacuum, and a leak-checked, reassembled circuit. It concludes with an accurate recharge using the specified refrigerant and lubricant, followed by final pressure and temperature checks to ensure the system operates within the manufacturer’s design envelope. In such a sequence, every action supports the next, and the chapter’s emphasis on evacuation becomes the spine of the entire service operation. For readers who want to explore more practical perspectives grounded in day-to-day maintenance, the KMZ Vehicle Center Blog offers a broad range of maintenance insights that complement the evacuation-focused discipline described here. KMZ Vehicle Center Blog.

In closing, the evacuation phase is the quiet yet essential gatekeeper of successful HFC-134a servicing. It is where theory meets practice, where the integrity of the refrigerant is preserved, and where the system is prepared for a reliable recharge that will deliver comfort, efficiency, and safety to the vehicle’s occupants. The disciplined application of the deep-vacuum procedure, the strict avoidance of refrigerant release, and the adherence to certification and regulatory standards together define a responsible, effective approach to maintenance. For those seeking deeper, application-specific detail outside general practices, consult the referenced industry guideline documents and official service manuals that correspond to your vehicle make and model. In particular, you can access a targeted evacuation guideline for R-134a circuits through the appropriate external reference. Evacuation is not an optional step; it is the essential mechanism by which the integrity of the entire air-conditioning system is protected during service. As you prepare for the recharge, you stand on a foundation that supports durability, performance, and environmental stewardship. External reference: https://www.valeo.com/content/dam/valeo/technical-documents/evacuation-guidelines-r134a.pdf

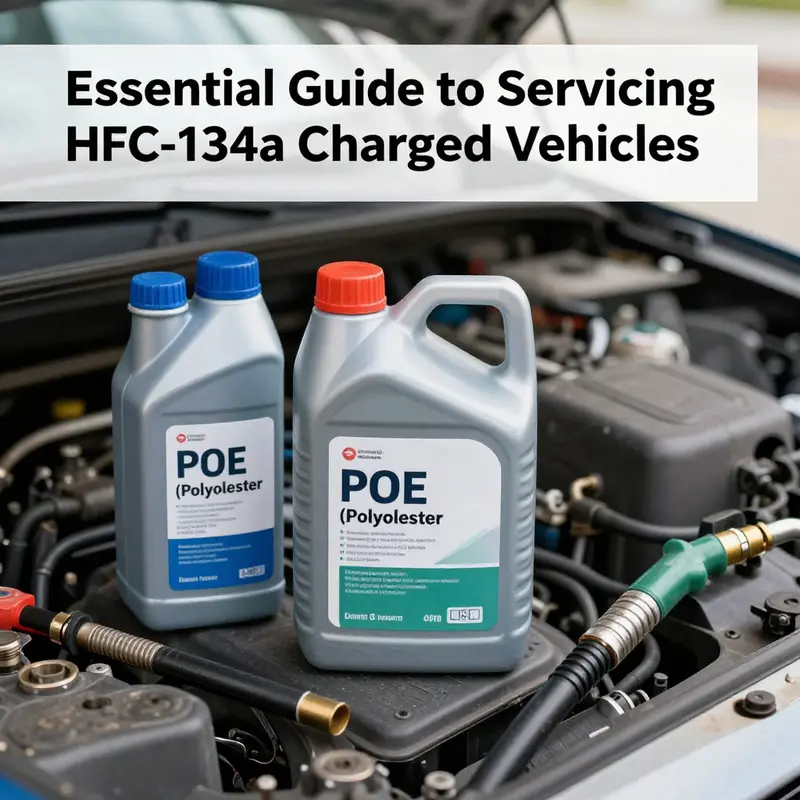

Lubricating the Heart of an HFC-134a System: Why Correct Refrigerant Oils Matter When Servicing

Oil sits at the intersection of chemistry and mechanical design in an HFC-134a air conditioning system. The refrigerant might grab attention with its low environmental impact and its own thermodynamic properties, but without the right lubricant, the compressor cannot maintain the kind of reliability modern vehicles depend on. In most systems charged with HFC-134a, the lubricating oil is a polyol ester, or POE, designed to stay compatible with the gas through a wide range of temperatures and pressures. The oil’s job is not simply to damp bearing wear; it coats moving surfaces, helps seal clearances, and carries heat away from the compressor chambers. Servicing with incorrect oil undermines all of these functions, and the consequences cascade through the entire climate control loop.

Beyond compatibility, the moisture sensitivity of POE oils makes handling during service critical. POE lubricants readily absorb water from the environment, and moisture in the oil can react with refrigerant to form acids that attack seals and metal surfaces. For that reason, technicians must preserve a dry oil system during service, avoid prolonged exposure of opened containers, and minimize the time the system remains open to atmosphere. This is why the procedures call for a thorough evacuation and a controlled introduction of replacement oil and refrigerant after the system has been dried with vacuum. Even small increases in moisture content can alter refrigerant performance, raise the risk of corrosion, and shorten compressor life, especially in high-load conditions.

Because HFC-134a systems vary in hardware and flow paths, the exact oil type and viscosity are not universal. Manufacturers specify an oil grade and sometimes a viscosity range tailored to their compressor design and seal materials. The policy across modern vehicles is to use the oil the manufacturer lists, and to respect the exact quantity that accompanies a refrigerant charge. The policy across modern vehicles is to use the oil the manufacturer lists, and to respect the exact quantity that accompanies a refrigerant charge. Getting this right matters because the oil must circulate with the refrigerant, lubricate bearings under pressure, and maintain a stable film across the piston and vane surfaces where heat is generated. When the wrong oil is used, the lubricant can break down under operating temperatures, creating carbonized deposits, sludge, and increased friction. That combination quickly erodes efficiency and can lead to premature component failure even if the system holds the correct refrigerant charge.

Oil quantity is not a guess; it is part of the system’s charging procedure. Some compressors carry a known oil share, while others rely on the oil introduced with the service refrigerant to return to the compressor via pressure differentials. The service manual for each vehicle usually specifies an oil charge that accompanies a full refrigerant charge. When you evacuate and recover refrigerant, you may also remove oil from the system; you should plan to add the exact amount back with the new refrigerant. Deviations from the spec can ruin lubrication balance, cause foaming, or prevent proper oil return through scrolls or pistons. The practical takeaway is simple: verify the oil type, verify the quantity, and verify the method with the vehicle’s official documentation.

When contamination exists, the only reliable remedy is to address it at the source. If a repair has left mineral oil residues in an HFC-134a circuit, flushing or a careful oil-change procedure may be required to restore lubrication integrity. In practice, many vehicles cannot tolerate mineral oil in a POE environment, and even small pockets of mineral oil can alter lubrication properties enough to degrade efficiency. If a technician suspects cross-contamination, they should follow the manufacturer’s guidance on flushing, drying, and recharging. This is not merely a matter of preference; it is about preserving system chemistry and the positive interplay between lubricant and refrigerant that makes the cooling cycle predictable and stable under varying load.

During a service, the procedure should begin with checking the refrigerant charge and oil specifications in the official service manual, then isolating the system, recovering the old refrigerant with a certified machine, and drying the system to the recommended moisture level. Only after achieving the proper dryness should the oil be introduced, followed by the precise refrigerant charge. This sequential discipline prevents moisture and air from entering the oil path, preserving lubrication efficiency and heat transfer. As you consider the broader maintenance picture, you can also benefit from cross‑linking knowledge about engine oil planning; for example, see optimal oil-change intervals time vs mileage for a sense of how oil management affects long-term reliability across vehicle systems. Keeping the lubrication cycle clean is not only a matter of daily operation; it also supports longevity between major service events.

From a compliance perspective, the service workflow aligns with regulatory intent to minimize environmental release of refrigerants. The refrigerant oil choice is not a cosmetic detail, but part of a controlled chemistry that helps keep the system contained and efficient. Reputable service practice includes verifying that refrigerant recovery and recycling equipment is functioning, verifying leak-free connections, and ensuring that the evacuation is complete before introducing new refrigerant. The aim is to prevent oil from becoming a conduit for contaminants or moisture into a sealed circuit. By respecting the oil specification and the associated handling procedures, technicians contribute to reliable climate control while protecting the broader environment.

When malign oil choices slip into a system, the symptoms can appear early or late but are generally predictable. Expect higher suction temperatures, louder compressor operation, or reduced cooling capacity. Sludge and varnish can cloud the oil, lowering its viscosity and interrupting oil return. Regular checks during service—measuring oil residue, confirming refrigerant oil ratio, and validating the absence of moisture—help catch problems before they escalate. The best defense is a disciplined process: consult the manual, maintain clean tools and containers, and never substitute oils without explicit approval. In the end, the oil is the unsung partner in the refrigerant’s journey, and safeguarding it is essential to preserving comfort, efficiency, and vehicle longevity.

All of these considerations come together in a simple principle: treat the oil as an active, critical part of the refrigerant circuit, not as a bystander. When you service a vehicle charged with HFC-134a, you should approach oil selection and oil management with the same rigor you apply to refrigerant handling. The goal is to maintain viscosity, minimize moisture, and ensure complete oil return to the compressor over the system’s operating range. By staying aligned with the vehicle’s official documentation and industry best practices, technicians can deliver a climate-control system that remains efficient, durable, and quietly dependable for years to come.

For official guidance on refrigerant handling and oil compatibility, see EPA Section 609: https://www.epa.gov/section609

Precision, Purity, and Compliance: Servicing a Vehicle Charged with HFC-134a

Servicing a vehicle charged with HFC-134a is a disciplined process that prioritizes precision, purity, and environmental responsibility. The refrigerant must be recovered, purified, and recharged by weight using equipment that meets established standards such as SAE J2788. The objective is to preserve refrigerant quality, minimize contaminants, and ensure the correct charge without compromising the system or the environment. Key steps include evacuating air and moisture, recovering the refrigerant, drying and filtering to remove acids and particulates, and recharging to the manufacturer’s specified target. Accurate weighing, maintenance alerts for the dryer and filters, and post-recharge leak checks help ensure long-term reliability. Throughout the service, technicians follow the vehicle’s service manual to verify oil compatibility and refrigerant type, maintain system integrity, and verify that cooling performance meets original specifications. Adherence to standards and proper documentation supports safety, regulatory compliance, and environmental stewardship.

Relying on the Official Service Manual: Precision and Safety When Servicing a Vehicle Charged with HFC-134a

When a technician approaches a vehicle charged with HFC-134a, the most important starting point is clear: consult the official service manual for that specific make and model. The manual is more than a checklist; it is the repository of the manufacturer’s tested procedures, pressure specifications, oil types, refrigerant charge levels, service port locations, and torque values that differ from one vehicle to another. Relying on memory or generic guidance invites risk. The manual captures the unique geometry of each system, the layout of the refrigerant circuit, and the sequence of steps that prevent harm to the vehicle, the technician, and the environment. In practice, this means using only HFC-134a refrigerant aligned with the vehicle’s stated type and capacity, and ensuring compatible lubricants, typically polyolester oils, are used when the manual specifies them. Even small differences in oil compatibility can impact compressor performance, oil return, and system longevity. A careful review of the manual before any discharge or connection helps the shop avoid overcharging or undercharging, which can lead to poor cooling performance or accelerated wear. It also guides technicians on correct procedures for safety devices, refrigerant reclamation, and the sequence for disconnecting and reconnecting service lines. The manual’s guidance is not a formality; it is a practical map for precise work, minimizing the chance of accidental release and ensuring compliance with environmental regulations that govern refrigerant handling in modern vehicles. The emphasis on precision is a direct reflection of how the industry now treats refrigerants as both critical cooling media and regulated substances with real environmental consequences when mishandled. The chapter of service information that covers charge amounts, allowable pressures, and the exact oil specification is the touchstone for any repair, replacement, or diagnostic operation. It is through that lens that every other consideration—from recovery equipment to leak testing—takes its proper place in a coherent workflow. The manual also speaks to the human factors of service work. It prescribes steps to verify that the correct port adapters and hoses are used, that the refrigerant cylinders are compatible with the system, and that the technician attends to material safety data sheets and personal protective equipment requirements. In short, the manual preserves both safety and sound engineering practice during every service action. For technicians who are new to a model or for those handling a fleet with multiple makes, this emphasis on a single, reliable source helps maintain consistency across technicians and shifts, which in turn protects the customer and the vehicle’s performance long after the service is completed. A well-executed service not only maintains cooling efficiency but also reduces the risk of moisture intrusion, which can lead to acid formation and corrosion within the system. The official manual provides explicit instructions on how to perform vacuum evacuation to remove air and moisture before charging. It sets the stage for accurate refrigerant charging by specifying the target vacuum level and the final system pressure after charging. These parameters are not arbitrary; they reflect the design tolerances of the compressor, condenser, evaporator, and expansion device. When followed, they yield a system that operates at stable pressures, with reliable lubricant flow and proper oil circulation. The consequences of deviating from these guidelines can be subtle at first, such as diminished cooling capacity or fluctuating pressures, but over time they can evolve into more serious faults like compressor seizing or accelerated seal wear. The manual also covers the correct handling of service equipment, including recovery and recycling machines. In practice, the procedure begins with recovering any remaining refrigerant before opening the system, then evacuating to the prescribed vacuum level, and finally charging with the precise amount of refrigerant and oil as specified. Many modern service manuals also include steps for diagnosing leaks through pressure testing and leak detection, often with recommended leak test methods that minimize environmental release. In this sense, the official manual serves as a safeguard that aligns shop practice with regulatory expectations and the manufacturer’s warranty conditions. Within the broader context of vehicle maintenance, treating refrigerant service as a disciplined procedure rather than a quick fix pays dividends in reliability and customer satisfaction. The manual’s guidance on component replacement is equally important. When a compressor, valve, or condenser is replaced, the manual will specify not only the correct refrigerant flow path but also the exact oil charge, the preferred oil type, and the orientation of new components to ensure proper lubrication from the moment the system is first run. This level of detail helps prevent wear irregularities and provides a clearer path to diagnostic success if future issues arise. It is a professional practice to verify the system’s resting state after service—confirming that all connections are secure, diagnostic codes are cleared if applicable, and that the system holds a stable vacuum before introducing refrigerant. The discipline of following the official service manual reduces variability and supports consistent outcomes across technicians and vehicles. As readers pursue a deeper understanding of refrigerant service, they may benefit from open resources that discuss routine maintenance and best practices in a broader shop context. For ongoing insights and practical perspectives on maintenance workflows, the KMZ Vehicle Center blog offers related discussions on shop practices and equipment care, which can complement the formal manual’s guidance. See https://kmzvehiclecenter.com/blog/ for more context and ideas that reinforce the disciplined approach described here. Ultimately, the core takeaway is simple: when dealing with a vehicle charged with HFC-134a, you should rely on the official service manual as the governing source. It is the conduit through which safety, regulatory compliance, environmental stewardship, and mechanical integrity converge into a single, repeatable process. The manual ensures you respect the system’s design, apply the correct lubricants, follow the approved recovery and evacuation steps, and charge accurately with the proper refrigerant quantity. It anchors service quality to the vehicle’s unique specifications rather than to generic rules that may not apply. For those who seek an official external reference on environmental practices related to refrigerants, the Environmental Protection Agency provides authoritative guidance on handling and reporting under the MVAC regulations. This resource reinforces the responsibility that comes with servicing vehicles that use refrigerants and highlights the broader regulatory framework that governs venting, disposal, and release control. External resource guidance aside, the practical, day-to-day certainty comes from reading and applying the specific manual for each vehicle. In this sense, the chapter serves not only as guidance but as a reminder of the professional standard that governs modern air conditioning service. The manual is where theory meets practice, where safety margins are defined, and where the long-term performance of the system is safeguarded. As technicians move through service calls, they are reminded that every fastening, every connection, and every vacuum cycle is part of a tightly coordinated sequence designed to protect people, protect the environment, and protect the customer’s investment. For those who want to explore more about general maintenance perspectives and shop workflows, the KMZ Vehicle Center blog linked earlier provides practical context that complements the formal procedures described here. External resource: https://www.epa.gov/mvac

Final thoughts

In conclusion, servicing vehicles charged with HFC-134a requires careful adherence to manufacturer specifications and standard best practices to ensure efficiency and compliance. By utilizing only approved refrigerants, following proper evacuation protocols, using the correct lubricants, employing recovery and recycling systems, and referencing the official service manual, car owners and fleet operators can maintain their vehicles effectively while being environmentally responsible. Adopting these measures not only enhances vehicle performance but also contributes positively to the overall health of our planet.