Navigating vehicle maintenance can be daunting, especially when it comes to understanding service modes. Whether you own a Tesla, an Audi, or any other make, knowing how to activate service mode is crucial for diagnostics and repairs. This guide empowers private car owners, used car buyers, sellers, and small business fleet operators alike with detailed strategies for entering service mode across various vehicles. Each chapter will unfold essential steps, guidelines, and considerations that are integral to ensuring your vehicle operates safely and efficiently.

null

null

null

null

Inside Service Mode: Navigating Diagnostic Access and Safe Maintenance Across Modern Vehicles

Service mode stands as a quiet gatekeeper in the chassis of a modern vehicle. It is a tool designed not for everyday driving but for diagnostics, calibration, and tests that reach deep into the car’s brain. This is a realm regulated by manufacturers, guarded by safeguards, and accessible only when the operator has legitimate credentials and a clear purpose. The purpose of this chapter is not to teach how to bypass safeguards or to empower reckless tinkering. It is to illuminate what service mode is, how it should be approached, and why it demands respect. Across makes and models, service mode is a specialization—one that exists because the complexity inside today’s automobiles cannot be understood or repaired by guesswork alone. The moment you step into service mode, you step into a space where software and hardware interact with tight tolerances, where a single misstep can ripple through safety systems, and where the line between normal operation and diagnostic access becomes blurred. The best approach is to treat service mode as a professional tool, to be used sparingly, with proper authorization, and with an eye toward safety above convenience. When we speak of service mode, we are really talking about a controlled corridor: a place where technicians can reach the vehicle’s hidden settings, run diagnostics, perform software updates, and conduct subsystems testing that is not ordinarily exposed to the driver. The corridor is necessary because modern vehicles consist of dozens of subsystems that must be coordinated precisely. The very act of entering service mode signals a shift from the persona of a driver to that of a technician, and with that shift comes responsibility. It is this responsibility that anchors every note you will read here.

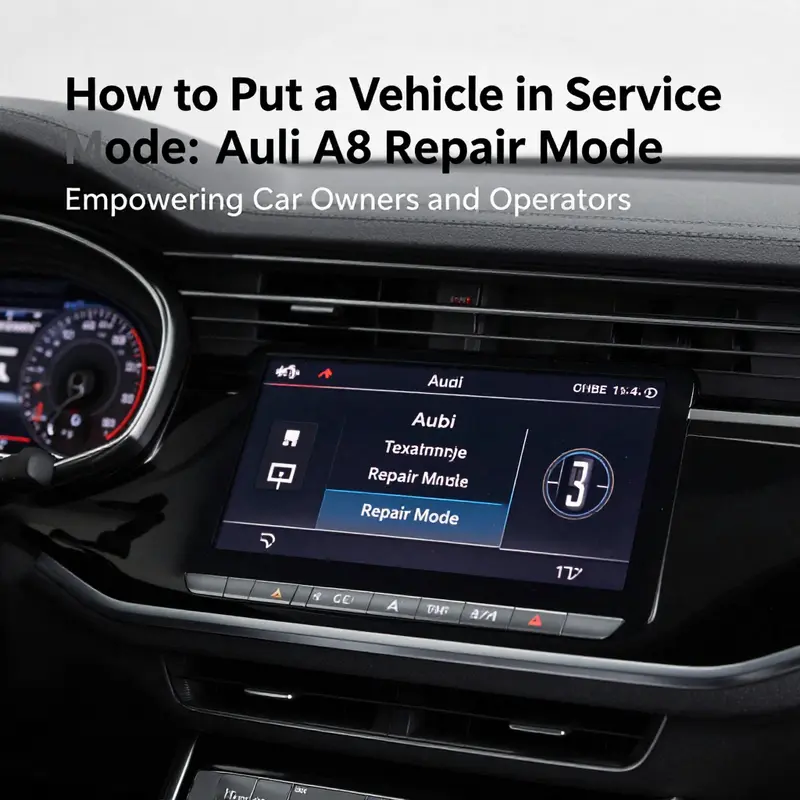

In practical terms, the general path to service mode across different brands follows a familiar rhythm even if the exact steps vary. The journey begins in the vehicle’s central interface—the touchscreen or control console you already rely on for navigation, climate control, and media. You navigate through menus labeled with familiar words like Settings, System, Software, or Maintenance. Within that realm, there is often a hidden tier—a special-access point designed to keep casual users from accidentally strolling into sensitive diagnostics. The hidden tier is not a trap for those who stumble upon it but a gateway that requires intentional action and proper authorization. In some brands, discovery hinges on a deliberate gesture rather than a straightforward tap. For example, a vehicle might reveal an access prompt after a specific interaction with the vehicle’s model badge on screen. A long-press on the badge can trigger the system to reveal an input field or a keyboard. The ripple effect that follows is more than a visual flourish; it is a cue that you are entering a protected zone. Such a design protects both the vehicle and the vehicle owner from inadvertent misconfigurations and from casual tinkering.

Once the access point is revealed, the next layer is an access code. The exact code varies by manufacturer and, often, by model or software version. Some technicians use a simple word or phrase; others rely on more complex sequences that are issued through authorized channels. The key point is that codes are not guesses. Entering the wrong code or attempting repeated guesses can trigger security alerts, lockouts, or additional safeguards. The process is meant to be precise and auditable, not informal. When the correct code is entered, the system typically transitions into a distinct visual state that signals the new mode. You might see a color shift, a border around the display, or a dedicated SERVICE menu appear. The interface’s confidence is read not only in the word “SERVICE” but in the way the system communicates that the vehicle has entered a diagnostics or maintenance context. This state is deliberate, expected, and designed to remind the operator that non-driving operations have begun. The exact visual cues vary by brand, but the underlying principle is universal: service mode is a diagnostic workshop inside the car, and with that workshop comes responsibility.

The implications of enabling service mode are substantial. While the door is open to diagnostics, many safety features are disabled, or their behavior is altered. This is not a setting to be engaged for leisure driving or for casual experimentation. It is a framework in which the vehicle’s software and hardware can be tested, calibrated, or diagnosed under controlled conditions. The suspension may be raised to facilitate maintenance access, actuators might enter test sequences, and sensors could be queried for calibration data. All of this is invaluable to trained technicians who perform maintenance, troubleshooting, or software updates. Yet it also opens risk avenues: a miscalibrated subsystem could affect handling, stability, or braking performance, and unexpected results can cascade into unsafe conditions. The overarching rule is simple and inflexible: never operate the vehicle in service mode for the purpose of regular driving. If you must test outside of a garage or service bay, you should be in a supervised, authorized setting with a technician present who can monitor safety-critical systems and stop tests if anything deviates from safe parameters.

Close attention to procedure is part of the discipline of service mode. The exact steps will vary, but there are shared principles that help keep the process safe and purposeful. Before attempting to enter service mode, confirm that you have authorization and that the vehicle is in a safe location for work. The vehicle should be placed in a stable state, with keys present only in a controlled manner, and with the environment free from hazards. Once inside, avoid making changes beyond the scope of the intended diagnostic or maintenance task. The temptation to explore‘hidden’ features should be tempered by a clear plan: what you intend to diagnose, what measurements you expect, and what you will do if something nonstandard appears. Documentation is a silent partner in this work. Keeping a record of the exact steps taken, the codes entered, and the tests run is essential for safety, warranty considerations, and future maintenance work. In many service operations, a back-out plan is part of the protocol. If a test or calibration fails or reveals an anomaly, technicians often revert to known-good configurations to prevent drift from safe parameters.

A practical thread running through this topic is the balance between accessibility and control. Manufacturers intentionally place service mode behind controlled gates. They do this not to complicate ownership but to protect the vehicle’s integrity and the safety of its occupants. A close look at this balance reveals a design philosophy: the privilege of entering service mode comes with boundaries. Those boundaries can be conceptual—such as a prohibition on driving during service mode—or procedural—such as requiring a service appointment, a service center location, or the use of toolsets and software that are not publicly available. The result is a system that favors professional, authorized maintenance while discouraging casual tampering. For owners and enthusiasts who crave more practical insight, the message is clear: service mode is a specialized capability, not a feature for casual experimentation. Respect for the limitations and the process will protect both the vehicle and the person operating it.

To illustrate how this plays out in the real world, consider two archetypal patterns within service mode. In one, an electric‑drivetrain platform uses a gesture-based unlock that requires an intentional interaction with the display—such as a long-press on the model badge—to reveal a secure field for an access code. The gesture acts as a humorless gatekeeper, signaling to the software that the operator is prepared to proceed with a professional task. In another pattern, a luxury sedan features a multi-step menu path that leads to a dedicated maintenance function, often labeled with terms like Vehicle Maintenance or Related Functions, and then into a domain where a repair or diagnostic sequence begins. The sedan’s system might reconfigure its suspension to a raised stance to provide safer access to mechanical components, while the technician connects diagnostic tools to verify system health. In both cases, the essence is the same: service mode is not a casual unlock; it is a defined toolset for diagnosis, testing, and safe maintenance operations. The practical upshot for readers is straightforward. If you are not a trained professional with legitimate access, do not attempt to enter service mode. If you are a technician, proceed only with proper authorization, the right tools, and a clear purpose.

The broader context for any discussion of service mode includes the importance of manufacturer guidelines. These guidelines are not bureaucratic obstacles; they are built on years of engineering experience and safety testing. They specify what is permissible, under what conditions, and with what safeguards. They also constrain the kinds of changes you can make and require documentation for service actions. This framework protects warranties, supports accurate diagnosis, and reduces risk for vehicle owners and the public. When you encounter a service mode label in a manual or a display, treat it as a professional tool. Do not treat it as a shortcut to personal customization or performance tinkering. The design philosophy behind service mode—protective, purpose-driven, auditable—reflects the broader evolution of automotive technology toward more integrated, software-defined vehicles. As complexity grows, so too does the importance of disciplined access. The chapter you’re reading is not meant to provide a cheat sheet but a balanced view of why service mode exists, how it is accessed, and how to engage with it responsibly.

For readers seeking grounded guidance, the path is to consult official manuals and speak with authorized service personnel. While online articles can sketch the landscape, they can never substitute for the precise, model-specific instructions that come from the manufacturer’s documentation. If you are researching this topic for technical writing, repair planning, or vehicle maintenance oversight, lean on the documented procedures that accompany your specific vehicle, and keep a record of any service actions performed. A good practice is to align your practice with the service center workflow, which is designed to ensure traceability, accountability, and the safety of the vehicle and its occupants. In addition to manuals, many manufacturers provide service documentation at their official support portals. These portals often include model-specific notes, cautionary statements, and step-by-step sequences that reflect the latest software versions and hardware configurations. When in doubt, err on the side of caution, and seek direct guidance rather than improvising in the field.

As you navigate these considerations, it is helpful to anchor your understanding in a few reliable sources and reference points. For those exploring practical maintenance content related to vehicle care and diagnostics, a dependable starting point can be the broader automotive maintenance literature and the service knowledge base of established repair hubs. These resources can offer context on how service mode fits into routine maintenance schedules, the typical kinds of diagnostics that are performed, and the reasons why certain procedures must happen in controlled environments. They can also provide background on how service mode interacts with safety systems, software integrity checks, and the calibration of subsystems that can be sensitive to timing, torque, or sensor drift. When you’re ready to expand beyond general concepts, you can turn to manufacturer resources and official guides that spell out the exact steps for your vehicle’s year, trim, and software version. Keep in mind that the specifics matter, and even minor version differences can alter the procedure or the expected outcomes.

If you’re seeking further practical interpretation and community-tested insights, a respected resource hub is available to readers who want to dive deeper into safe maintenance practices and vehicle care narratives. For a curated collection of maintenance guidance and related topics, you can visit the kmzvehiclecenter blog. It offers broader coverage of vehicle upkeep, diagnostics, and preventative maintenance, which can complement the understanding of service mode without replacing manufacturer documentation. The link below points to that resource hub:

In sum, service mode is a deliberate, guarded feature in modern vehicles. Its purpose is clear: to enable engineers and technicians to access deep systems for diagnostics, calibration, and safe maintenance while preserving overall vehicle safety and security. The steps, while conceptually straightforward, are intentionally safeguarded and vary by brand, model, and software version. The responsible practice is to seek proper authorization, use model-specific manuals, and treat any access as a controlled operation rather than a convenience feature. This mindset protects not only the vehicle but also the people who rely on it every day. For ongoing learning and practical context beyond the model‑specific procedures, remember that official manufacturer documentation is the most reliable guide, and that authorized technicians are the best point of contact when service mode becomes necessary. As you continue your exploration of the topic, keep safety at the forefront, stay aligned with guidelines, and approach service mode as the professional tool it is, not a casual setting to press, poke, or experiment.

External reference for official guidance: https://www.tesla.com/support/vehicle-service-mode

Into the Service Zone: Why Manufacturer Guidelines Shape Safe Vehicle Diagnostics and Maintenance

Service mode sits at the intersection of capability and caution. It is not a casual toggle you flip for a quick fix; it is a carefully guarded tool that allows trained technicians to access core systems, run diagnostics, and reinitialize subsystems after service. The purpose is clear: give authorized personnel a precise, low-risk means to diagnose faults, calibrate sensors, and verify that repairs restore the vehicle to the performance and safety standards required by regulators and manufacturers. Yet the moment you step outside the boundaries set by the maker, the risks multiply. Safety interlocks can be overridden, protective features can be temporarily disabled, and even a minor misstep can cascade into post-repair faults that manifest as erratic behavior, unexpected warning lights, or degraded performance. This is why the chapter you are reading treats service mode as a specialized, model-specific function that must be guided by official documentation and trained technicians rather than consumer curiosity or ad-hoc experimentation.

The key nuance is that service mode is not a universal switch in modern vehicles. As the industry pivots toward electrification, autonomous features, and frequent OTA software updates, manufacturers have layered stricter controls around diagnostic access. The regulatory landscape has also evolved in significant ways. In the wake of electrification and intelligent driving, access to deep vehicle systems is increasingly scrutinized to prevent tampering, preserve cybersecurity, and maintain safety certifications. A growing body of guidance at the national and international level emphasizes that software access should be tightly controlled and that only authorized technicians—with verified credentials and supported by official tooling—should perform operations that could affect vehicle safety or emissions readiness. The point of these measures is not to slow maintenance but to ensure it happens without compromising the integrity of critical systems or the regulatory status of the vehicle.

To understand why these boundaries exist, it helps to consider the diversity of approaches across manufacturers. Service mode arrives at the vehicle through distinct pathways, each tailored to the architecture of that brand’s electronics, software, and hardware subsystems. In broad terms, you can think of two recurring patterns. One pattern is an interface-driven path that begins in the vehicle’s on-board display or control screen. From a designated area—often labeled in neutral terms like “Diagnostics” or “Software”—an access code is required to unlock a protected menu. The act of entering that code is deliberate and auditable. In some cases, the interface may require a specific gesture—such as long-pressing a model identifier on the screen, or invoking a hidden gesture that signals technician intent. When the code is accepted, the system presents a dedicated service menu with the diagnostic tools needed for deep system checks, software reinitialization, or calibration. The color cues, prompts, and safeguards that appear in these menus are not cosmetic; they are designed to visually remind the operator that a high-safety, high-stakes operation is underway.

The second pattern moves service mode into the realm of maintenance workflows that blend software permissions with physical actions. In this approach, a service pathway opens through the vehicle’s maintenance or repair submenus, often requiring confirmation steps, alignment with service codes, and in some cases interaction with vehicle subsystems that can perform controlled physical changes. A common example is a maintenance mode that allows safe servicing of suspension or chassis functions, letting the technician raise or stabilize components without triggering protective interlocks in ordinary operation. This pathway reinforces the principle that service mode is not merely a diagnostic helper; it is a controlled environment tuned to keep the vehicle stationary and predictable while complex work is performed. The underlying design is simple in intent—protect the technician, protect the vehicle, and protect future occupants—yet the execution must be precise, authenticated, and documented.

If you move through the day-to-day work of a maintenance facility, you will see that the same principle applies across brands and platforms: there is a deliberate separation between consumer-use modes and the deep, service-oriented modes. This separation is as much about governance as it is about mechanics. When a technician enters service mode, they are not just accessing a broader toolkit; they are entering a state in which the vehicle’s safety, powertrain integrity, and driver-assistance systems are treated as reconfigurable only under strict oversight. The consequence of a misstep is not merely a diagnostic delay. It can be a cascade of miscalibrations, feature misalignments, or even a reset that leaves the vehicle unfit for its required regulatory checks. That is why manufacturer guidance is presented as both a precaution and a procedural map, with steps that are concise, verifiable, and traceable.

The practical takeaway for technicians and curious readers is that every model family has its own explicit sequence, its own validated tools, and its own set of safety preconditions. Even when the same broad objective—diagnostic access, post-repair verification, or software recalibration—is pursued, the path to get there is designed to harmonize with the vehicle’s entire electronic ecosystem. The manufacturer’s manual is not a mere advisory. It is the single most authoritative source, outlining user roles, required qualifications, and the precise steps that engineers validated during development and testing. Adherence to this document preserves warranty protections, ensures regulatory compliance, and minimizes the risk of latent faults after service.

Consider, for a moment, how this guidance translates into practice on the shop floor. A technician prepares for a diagnostic session by verifying the vehicle identity, the service authorization, and the alignment of the service tooling with the vehicle’s software version. The technician then navigates to the official pathway for service mode, following prompts that reflect the model’s software architecture. In some interfaces, a seemingly small action—like selecting a model badge and performing a controlled interaction—unlocks a gateway to a suite of diagnostic utilities. In others, the process may require entering a validated access code, one that is issued by the service center and logged within the maintenance management system. The pattern is consistent: entry is authenticated, the session is bounded by a defined scope, and the vehicle’s safety subsystems carry forward in a guarded state unless the technician explicitly requests an exception for a short, well-defined maintenance window.

The reasons for this design are not academic. Across the industry, a few centering themes recur. Safety and system integrity are the primary drivers. If a service session can disable airbags or alter brake calibration in an unchecked fashion, the risk to occupants and pedestrians rises sharply. Then there is regulatory compliance. As vehicle software becomes a moving target—patched OTA, feature updates, and cross-border certifications—the need to track who accessed which systems and what adjustments were made becomes critical for audits and for ensuring that a vehicle remains compliant with emissions and safety standards. Preventing unauthorized modifications is the third pillar. Service mode is a premium access point; granting it to untrained hands invites the possibility of unintended software alterations, compatibility issues, and new cybersecurity vulnerabilities. Finally, ensuring functionality after service is non-negotiable. A post-service verification sequence—comprehensive diagnostics, subsystem recalibrations, and readiness checks—helps guarantee that the vehicle returns to the road in a condition that the manufacturer and regulator can stand behind.

The best way to respect these principles is to internalize a few practical guardrails. First, always consult the official service manual or the technical documentation supplied by the manufacturer for the exact model and software version you are working with. Second, use only diagnostic tools and software that the manufacturer explicitly authorizes for that platform. Third, confirm that the technician performing the work is trained and certified by the manufacturer for the specific vehicle family involved. Fourth, never attempt to bypass or reverse-engineer service mode procedures. If a procedure seems ambiguous or inaccessible, the correct course is to pause, consult the official documentation, and coordinate with a service center that has the required authorization and safety clearances. These steps are not merely bureaucratic; they are the practical means by which a complex electronic system remains both serviceable and safe.

Interwoven with these practical steps are the broader implications raised by modern vehicle policy and industry governance. The balance between enabling rapid diagnostics and preserving safety is delicate, particularly as vehicles increasingly rely on software-defined features that can be updated remotely. The regulatory conversations—whether framed around access to critical software, cybersecurity standards, or the rationale for strict engineering controls—underscore a larger objective: to ensure that service actions do not undermine a vehicle’s safety envelope or its long-term reliability. In this sense, service mode is more than a tool to fix a problem. It is a controlled environment designed to sustain a vehicle’s lifecycle in the face of rapid technological change. Where this balance tips—toward convenience at the expense of safety, or toward security at the expense of timely maintenance—depends on the integrity of the governance surrounding the vehicle’s software ecosystem. The manufacturer’s stance on service mode is therefore a reflection of how that ecosystem has been engineered from the outset and how it will evolve as new capabilities, sensors, and intelligence layers are added.

As you navigate this landscape, remember that the objective extends beyond the moment of maintenance. A properly managed service session ensures that, once the work is complete, all systems re-enter readiness with a clear, verifiable state. The vehicle returns to service with the updated software and recalibrations correctly synchronized, and the technician can document the session to support warranty coverage and regulatory reporting. The long view is one of ongoing reliability and safety; that is the enduring rationale for manufacturer-guided service mode. For readers who are seeking consumer-friendly guidance that connects to broader maintenance topics, a look at the KMZ Vehicle Center blog offers practical perspectives on how routine checks and preventive maintenance intersect with the complex world of diagnostic modes. KMZ Vehicle Center blog

In sum, entering service mode is not a universal, do-it-yourself tweak. It is a doorway into a tightly governed technical space, where the steps are scripted by the maker, the tooling is verified by the factory, and the post-maintenance reinitialization is measured against strict safety and regulatory criteria. Respect for this framework protects technicians, preserves vehicles, and supports the rigorous certification processes that keep modern cars, trucks, and vans compliant and safe on the road. The next chapters will explore how these principles translate into practical workflows for different vehicle platforms, and how technicians reconcile the demands of fast-paced maintenance with the unwavering requirement for safety and accountability. For now, the guiding principle remains clear: when service mode is on the table, follow the manufacturer’s instructions precisely, rely on authorized tools, and treat the integrity of the vehicle as a responsibility shared by engineers, technicians, and regulators alike. Finally, keep in mind that the landscape is dynamic. OTA updates, evolving cybersecurity requirements, and new diagnostic paradigms mean that vendor manuals and service portals are living documents that respond to real-world experience and regulatory feedback. The history of service mode is still being written in workshops, service centers, and test houses around the world.

External resource for further reading: https://www.tesla.com/support/vehicle-service-manual

Final thoughts

Successfully entering service mode in your vehicle is essential for effective diagnostics and repairs. By understanding the specific requirements for your car model—be it a Tesla or an Audi—you can empower yourself as a private car owner or a small business fleet operator. It’s important to adhere to manufacturer guidelines and make informed decisions before engaging these modes to maintain safety and vehicle integrity.