Turbocharger maintenance is often overlooked, yet it is critical for those who want to keep their vehicles running at peak performance without facing hefty repair bills. The reality is that turbochargers can fail catastrophically, leading to extensive engine damage that could cost thousands to fix. Picture this: you’re on the road, and suddenly your turbo fails. The consequences are not merely inconvenient; they can drain your bank account and derail your plans.

However, by understanding the vital signs that indicate impending turbocharger failure, you can avoid such fate. This article aims to shed light on the key warning signs and maintenance strategies that ensure your turbocharged engine remains reliable. Stay tuned, because being proactive today can save you from the panic of costly repairs tomorrow!

Recognizing Early Signs of Turbocharger Failure

Recognizing early signs of turbocharger failure can help avoid costly repairs and ensure your vehicle continues to perform optimally. Here are some common signs to watch out for:

Common Signs of Turbocharger Failure:

-

Loss of Power and Poor Acceleration:

When the turbocharger is failing, it may struggle to provide the necessary boost, resulting in a noticeable loss of power and sluggish acceleration. You may find that your vehicle does not respond as quickly when you press the accelerator, which can impact your overall driving experience.

-

Excessive Exhaust Smoke:

If you see thick blue or black smoke coming from your exhaust, this could indicate that oil is leaking into the exhaust system due to worn turbo seals. This sign is a clear indication of turbo damage that should not be ignored, as it can lead to further engine complications.

-

Unusual Noises:

Listen for high-pitched whining or siren-like noises during acceleration. Such sounds often indicate damaged bearings or compressor wheels within the turbocharger that require immediate attention. Ignoring these noises can lead to complete turbo failure.

-

Increased Oil Consumption and Leaks:

If you notice you are frequently getting low on oil or see leaks around your vehicle, compromised turbo seals might be the cause. Increased oil consumption can result in oil pooling in the intercooler or intake pipes, leading to more significant engine trouble.

-

Check Engine Light Activation:

Modern vehicles are equipped with sophisticated onboard diagnostics. If your check engine light activates, it may be due to fault codes related to boost pressure or airflow sensors, indicating a malfunction in the turbocharger. Promptly addressing this issue can save you from more severe problems down the line.

Prevention Tips:

-

Regular Maintenance:

Follow the recommended maintenance schedule for your vehicle, including timely oil and filter changes, to ensure proper lubrication for your turbo. Regular checks can prevent contamination and promote a longer turbocharger lifespan.

-

Use High-Quality Oil and Filters:

Select high-quality synthetic oils and filters to maintain optimal lubrication for your turbocharger. Quality products can mitigate the risk of debris and contaminants, enhancing your turbo’s efficiency.

-

Allow Proper Cooldown:

After driving, let your engine idle for a minute, especially after heavy use. This cooling period before turning off the engine helps protect the turbo from heat-related damage.

-

Avoid Foreign Object Damage:

Regularly check your air filter to ensure it is clean and intact. A good air filter prevents debris from entering the turbocharger, protecting its internal components from damage.

-

Monitor Engine Performance:

Stay vigilant for changes in your engine’s behavior, such as unusual noises, excessive smoke, or performance issues. Early detection allows for prompt repairs, minimizing the risk of significant damage to the turbocharger.

Comparison of Turbocharger Failure Signs and Preventative Measures

| Turbocharger Failure Signs | Preventative Measures | Recommended Actions |

|---|---|---|

| Loss of Power and Poor Acceleration | Regular Maintenance | Schedule routine servicing every 5,000-7,500 miles. Monitor vehicle performance closely. |

| Excessive Exhaust Smoke | Use High-Quality Oil and Filters | Change oil per the manufacturer’s intervals with synthetic oil and high-quality filters. |

| Unusual Noises | Allow Proper Cooldown | Idle the engine for 1-2 minutes after heavy use before shutting it off. |

| Increased Oil Consumption and Leaks | Monitor Oil Levels | Regularly check oil levels and look for leaks; address any issues promptly. |

| Check Engine Light Activation | Engine Diagnosis and Regular Checks | If the check engine light comes on, get a diagnostic check and address any errors promptly. |

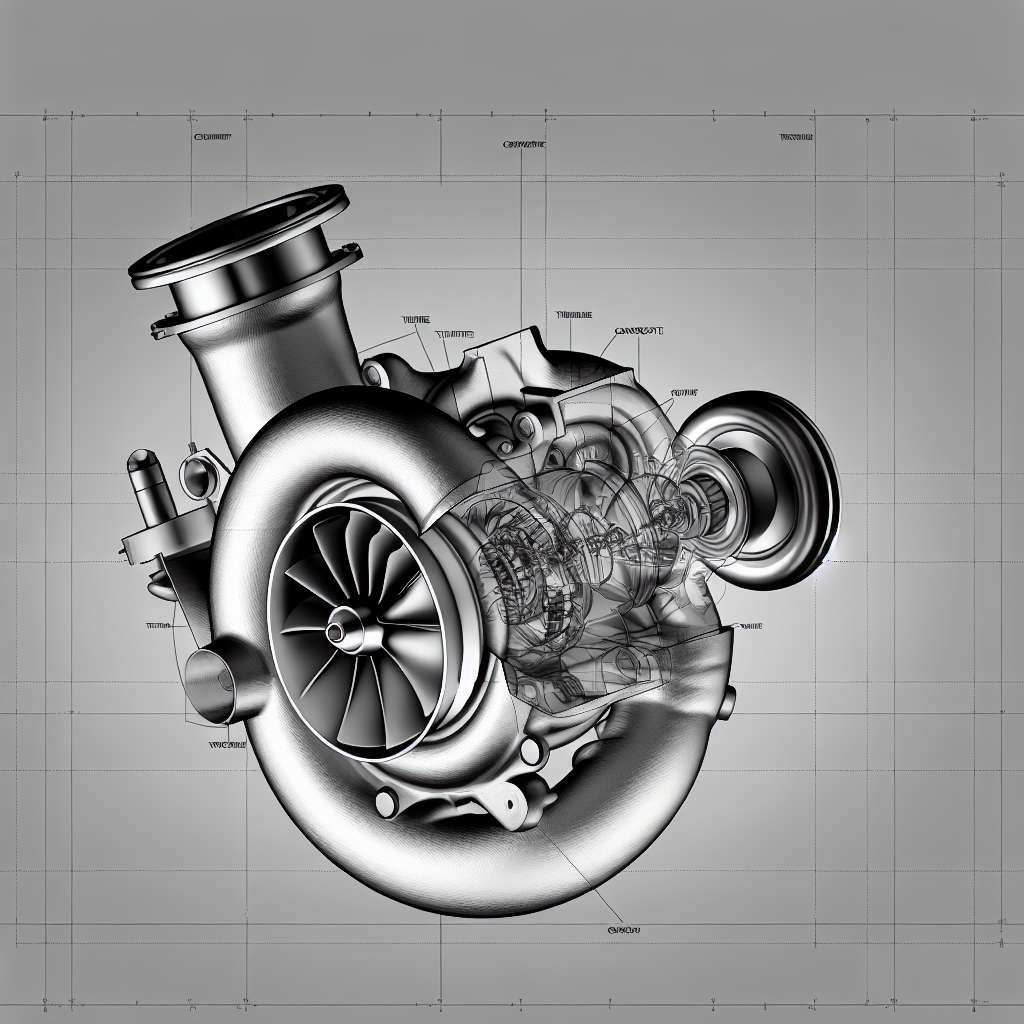

Evidence of Turbocharger Lifespan and Failure Causes

Maintaining a turbocharger is essential to extend its lifespan and prevent costly failures. According to extensive research, turbochargers can last upwards of 150,000 miles or longer with proper maintenance routines, but it’s crucial to recognize what can lead to catastrophic failure.

One of the most alarming statistics from Garrett, a well-known turbocharger manufacturer, highlights that over 90% of turbocharger failures stem from oil starvation or contaminated lubricants. This underlines the critical importance of maintaining proper oil levels and quality to prolong turbocharger life. Furthermore, Tom Wright, Group Product Manager at Melett, emphasizes that insufficient lubrication can lead to severe engine damage, stating:

“Once you run low on oil, even for a brief period, you can cause irreversible bearing damage.”

[melett.com]

Moreover, the high-performance nature of turbochargers demands optimal lubrication. Len Copeland from Daimler Trucks North America reinforces this point, saying:

“Running a turbo at near-zero friction levels is essential to maintain lower temperatures, making effective lubrication critical to engine health.”

[fleetmaintenance.com]

To prevent oil starvation, it is vital to carry out regular maintenance practices. This includes adhering to oil change intervals, using high-quality synthetic oils, and inspecting oil feed lines to ensure there are no obstructions. Another key recommendation is to avoid using silicone on oil gaskets, which can block oil passages and lead to significant engine problems. By following these best practices, drivers can enhance the reliability of their turbocharged engines and reduce the risk of detrimental failures.

In conclusion, the key to preserving both turbocharger efficiency and overall engine performance lies in proactive maintenance. Proper turbocharger upkeep is not just about avoiding breakdowns; it plays a significant role in extending the life of the engine as a whole. When turbochargers are routinely cared for—through timely oil changes, vigilant monitoring of performance signs, and adhering to manufacturer guidelines—drivers can enjoy a smoother, more responsive driving experience while avoiding hefty repair costs.

It is evident that neglecting turbo maintenance can lead to detrimental consequences, such as oil starvation that compromises engine health. To ensure longevity and optimal performance of turbocharged engines, adopting a comprehensive maintenance strategy is essential. By committing to these practices, drivers can maximize their vehicle’s potential while minimizing the risk of costly failures, thus enhancing the driving experience for years to come.

Embrace the responsibility of turbo maintenance today to safeguard your vehicle’s performance for the future!

Oil Change Intervals and Importance in Turbo Maintenance

Oil change intervals play a pivotal role in the maintenance of turbocharged engines. Given that these engines operate under extreme conditions, including turbos that spin at up to 350,000 RPM and temperatures exceeding 1,700°F, regular oil changes are not just recommended—they are essential for the health and performance of the engine.

Recommended Oil Change Intervals

Most manufacturers suggest changing the oil in turbocharged engines every 5,000 to 7,500 miles when using synthetic oil. If conventional oil is used, the interval may drop to every 3,000 to 5,000 miles. For instance, according to Ford, the oil for a 3.5-liter EcoBoost engine should be changed every 7,500 to 10,000 miles under normal driving conditions, while Subaru recommends an interval of 6,000 miles for its WRX turbocharged engines. These recommendations are crucial as neglecting them can lead to a range of performance issues.

The Consequences of Neglecting Oil Changes

Failing to adhere to recommended intervals can result in increased engine wear, turbocharger damage, and reduced overall performance due to contaminant buildup in the oil. Contaminated oil loses its lubricating effectiveness, leading to premature wear on engine components, particularly the turbocharger itself. More than 90% of turbocharger failures stem from oil starvation or contaminated lubricants, emphasizing just how critical this maintenance task is.

Common Misconceptions

Many drivers fall into the trap of believing that if they use high-quality synthetic oils, they can extend oil change intervals safely. Although synthetic oils have better resistance to breakdown, they still require regular changes, especially in turbo engines where oil is exposed to severe operational stress. Additionally, the assumption that longer intervals are safe fails to consider various driving conditions that may necessitate more frequent changes, such as stop-and-go traffic or extreme weather.

In summary, understanding the importance of regular oil change intervals in turbocharged engines is crucial for longevity and performance. Keeping these intervals in mind and adhering to them allows for better lubrication, significantly reducing the risk of costly turbo failures.

By making oil changes a priority, drivers can ensure that their turbocharged engines maintain optimal performance while remaining healthy for the long haul.

User Adoption of Turbocharged Engines

The adoption of turbocharged vehicles has experienced remarkable growth in recent years. In the United States alone, the prevalence of turbocharged engines in passenger vehicles surged from a mere 1% in 2000 to an impressive 37% by the 2023 model year. This trend reflects a significant shift in consumer preferences as drivers increasingly seek enhanced fuel efficiency and performance in their vehicles.

Turbocharged engines provide numerous advantages, including improved fuel economy, which can enhance efficiency by approximately 10-20% compared to naturally aspirated engines of similar power. This benefit, coupled with the capability of smaller turbocharged engines to deliver power levels comparable to larger naturally aspirated engines, underscores their appeal. For example, a 2.0-liter turbocharged engine can produce the same amount of power as a 3.5-liter engine, providing consumers with a balance of performance and reduced fuel consumption.

Additionally, as turbocharged engines gain traction in the market, there is a corresponding increase in awareness regarding maintenance practices essential for their longevity and reliability. Understanding the specific maintenance needs—such as regular oil changes and allowing the engine to cool down—has become crucial for consumers to optimize their driving experience and prolong the life of their turbocharged vehicles. The growing recognition of these factors contributes to the sustained popularity of turbocharged engines among drivers today.

Key Takeaways for Turbocharged Engine Maintenance

- Regular oil and filter changes are crucial to prevent oil starvation, which accounts for over 90% of turbocharger failures.

- Keep an eye out for loss of power, excessive smoke, unusual noises, and check engine light activations as signs of turbo issues.

- Allow the engine to cool down after driving to protect the turbo from heat damage.

- Use high-quality synthetic oils for better performance and reduced wear on the turbocharger.

- Conduct regular checks on air filters to avoid foreign object damage to the turbo and maintain optimal performance.