The need for preventative maintenance is crucial for diesel lift pumps. These pumps are essential for drawing fuel from the tank and sending it to the engine. Many vehicle owners neglect this maintenance, which can lead to various issues that impact vehicle performance and safety.

Ignoring the care of your diesel lift pump can cause hard starting, engine hesitation, and even severe fuel system failures. This not only results in costly repairs but can also cause unwanted downtime.

Proper maintenance, like regular filter changes and maintaining fuel quality, is vital for keeping the engine running smoothly. This overview highlights why preventative maintenance for diesel lift pumps is important, showcasing the benefits of diligent care and the dangers of neglecting it.

Importance of Lift Pump Maintenance

Regular maintenance of lift pumps is essential in ensuring the longevity and reliability of diesel engines. A lift pump plays a critical role in delivering fuel at the right pressure to the engine, making it the linchpin of the diesel fuel system. Neglecting its upkeep can lead to serious repercussions, including engine stalling, fuel inefficiency, and eventually a complete engine failure.

One of the primary issues arising from poor lift pump maintenance is engine stalling. According to Cummins Filtration, inadequate upkeep leads to fuel system contamination, which can cause the engine to shut down unexpectedly. The cost of repairs related to such failures can be staggering, with average repair bills ranging between $5,000 to $8,000 for comprehensive fuel system overhauls. Furthermore, a staggering 85% of common fuel system failures can be prevented with regular maintenance.

Corrosion is another concern linked to neglected lift pump maintenance. Water accumulation and contaminants that are not filtered out accumulate within the fuel system, potentially leading to microbial growth. This growth can rapidly deteriorate engine components, necessitating costly repairs. Fleet Maintenance Magazine has reported that 90% of lift pump failures are associated with vehicles that have surpassed 100,000 miles without consistent maintenance, indicating a pressing need for preventive measures in older vehicles.

Statistics from Equipment World indicate lift pump failures contribute to approximately 35% of all diesel fuel system-related breakdowns. Vehicles adhering to regular maintenance schedules experience 60% fewer failures, highlighting how even a proactive approach can save vehicle owners from unexpected downtimes and expenses. The average cost for lift pump repairs can range from $1,200 to $3,500, further affirming the financial benefit of routine maintenance.

In summary, regular maintenance of lift pumps is not merely an option but an essential element of vehicle care that ensures efficiency, reliability, and significant cost savings over time. By prioritizing routine inspections, filter changes, and monitoring fuel quality, diesel owners can avoid substantial repair costs and maintain optimal vehicle performance.

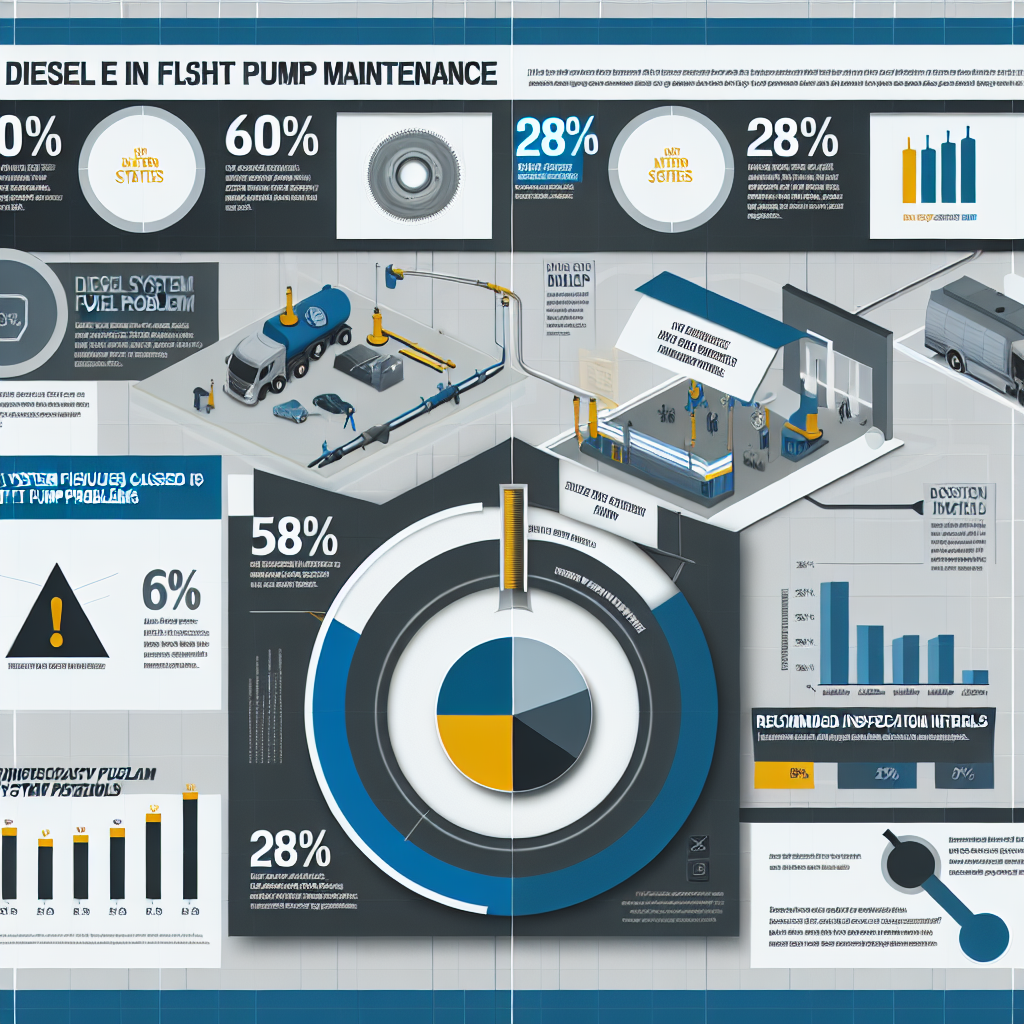

User Adoption Data for Diesel Lift Pump Maintenance

Understanding the adoption of maintenance practices for diesel lift pumps is critical for preventing failures and ensuring efficient operation. Recent findings highlight alarming statistics that showcase the need for improved maintenance adherence and practices among diesel users.

- Statistical Insights:

- According to a report from Diesel Power Magazine, 60% of diesel engine no-start issues can be attributed to problems within the fuel system, indicating that neglected lift pumps are a significant factor.

- The National Highway Traffic Safety Administration (NHTSA) reports that lift pump failures account for 28% of all diesel fuel system failures, reinforcing the necessity of consistent maintenance.

- User Behavior:

- A survey conducted by Equipment World reveals that only 35% of fleet managers adhere to recommended maintenance schedules for lift pumps, while those who practice regular maintenance experience 45% fewer fuel system failures.

- An academic study from SAE International indicates that merely 28% of diesel equipment operators follow suggested intervals for lift pump maintenance, contributing to increased failure rates.

- Maintenance Recommendations:

- Regular inspections should occur every 15,000 miles, while replacement is recommended around 100,000 miles or every five years, as per various expert guidelines.

- Best practices include continual pressure monitoring, utilizing OEM parts, maintaining fuel cleanliness, and immediate action concerning fuel contamination to significantly prolong lift pump life.

- Consequences of Neglect:

- The failure to maintain lift pumps can lead to critical operational failures, resulting in expensive repairs and unnecessary operational downtime, underlining the significance of adhering to maintenance schedules.

These insights illustrate a concerning trend of maintenance neglect, which risks raising costs and increasing equipment failure rates for diesel engine operators.

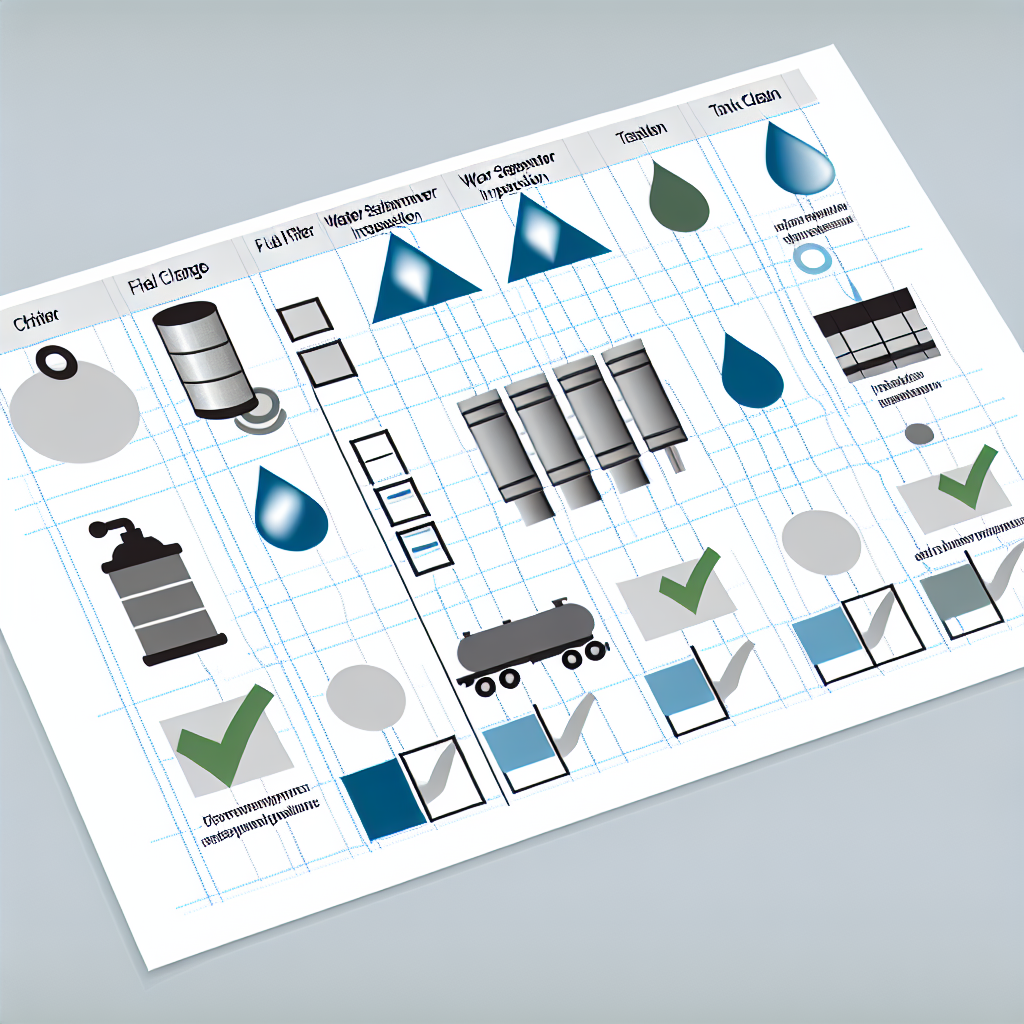

Maintenance Tasks for Lift Pumps

Maintaining lift pumps is critical for ensuring their longevity and efficient operation in diesel fuel systems. Here are specific tasks, recommended intervals, and practical tips to keep your lift pump functioning effectively:

1. Filter Changes

- Primary Fuel Filter: Replace the primary fuel filter every 15,000 to 25,000 miles or after 500 hours of operation. This prevents larger contaminants from entering the system. Neglecting this task can result in fuel starvation and engine issues.

- Secondary Filter: Change the secondary fuel filter every 1,000 hours of operation to ensure optimal fine filtration. Monitor this more closely in dusty or high-sediment environments.

2. Water Separator Maintenance

- Inspect the water separator every 250 to 500 hours of operation. Regularly drain it to remove accumulated water.

- Replace the water separator filter annually or as needed, especially if visual inspections indicate contamination or sediment build-up.

- If warning lights activate for water presence, service the separator immediately, as this can lead to corrosion and microbial growth.

3. Tank Cleaning

- Clean your fuel tank every 2,000 hours or once a year to prevent microbial contamination and sediment accumulation.

- During cleaning, flush the entire fuel system, replacing any deteriorated components as necessary.

- If you observe any sediment at the bottom of the tank during inspections, prioritize cleaning to ensure the fuel remains uncontaminated.

Practical Tips

- Incorporate visual inspections of the lift pump and associated components monthly. Check for any visible leaks, cracks, or corrosion that could signal impending issues.

- Use OEM-approved filters and parts to maintain system integrity and optimize compatibility.

- Maintain a detailed maintenance log to track intervals, ensuring tasks are not overlooked.

- Implement biocide treatments every few years or as needed to combat microbial growth, especially if water contamination is evident.

By following these maintenance guidelines, diesel vehicle owners can significantly reduce the risk of lift pump failures, extend the life of their fuel systems, and avoid costly repairs stemming from neglect.

| Component | Recommended Maintenance Interval |

|---|---|

| Lift Pumps | Inspect every 15,000 miles; replace every 100,000 miles or every five years. |

| Primary Fuel Filters | Change every 15,000 to 25,000 miles or after 500 hours of operation. |

| Secondary Fuel Filters | Change every 1,000 hours of operation. |

| Water Separators | Inspect every 250 to 500 hours; replace annually or as needed. |

| Fuel Tank Cleaning | Clean every 2,000 hours or once a year. |

Troubleshooting Guidance for Common Lift Pump Issues

Lift pumps are critical for the efficient operation of diesel fuel systems, and several common issues can potentially disrupt their performance. Below are symptoms associated with various problems and recommended solutions to tackle these issues effectively:

1. Hard Starting or No Start

- Symptoms: The engine cranks but fails to start, indicating lack of fuel delivery.

- Possible Causes: Fuel starvation due to a clogged filter, air intrusion, or electrical failure of the pump.

- Recommended Solutions:

- Check the primary and secondary fuel filters; replace them if heavily clogged.

- Inspect for air leaks in the fuel lines and fittings, ensuring they are tightly sealed.

- Test electrical connections to the lift pump for corrosion or damage.

2. Engine Stalling or Hesitating

- Symptoms: The engine hesitates during acceleration or stalls unexpectedly while running.

- Possible Causes: Insufficient fuel pressure caused by a failing lift pump.

- Recommended Solutions:

- Measure fuel pressure with a gauge; it should typically be between 5-15 PSI for most diesel engines.

- If pressure is too low, inspect the lift pump and replace if necessary.

- Consider checking injectors for cleanliness and functionality as a secondary measure.

3. Loss of Power Under Load

- Symptoms: Noticeable decrease in engine power during heavy loads (such as towing).

- Possible Causes: Impaired lift pump performance or contamination in the fuel system.

- Recommended Solutions:

- Inspect the lift pump output volume; ensure it meets specifications stated by the manufacturer.

- Check for any fuel contamination or debris buildup in the tank, and clean or replace as necessary.

4. Frequent Filter Clogging

- Symptoms: Filters clogging faster than expected, requiring frequent replacements.

- Possible Causes: Contaminated fuel or degraded lift pump.

- Recommended Solutions:

- Investigate the source of fuel; switching to a higher quality diesel fuel may help.

- Clean the fuel tank and ensure proper separation of water to prevent microbial growth.

5. Noises from the Fuel System

- Symptoms: Unusual whining or humming noises from the lift pump.

- Possible Causes: Mechanical failure or wear on pump components.

- Recommended Solutions:

- Listen carefully for irregular sounds; they may indicate impending failure.

- Consider replacing the lift pump if sounds persist after inspecting for blockages.

For further details on troubleshooting and fixes, refer to:

- Common Diesel Lift Pump Problems and How to Fix Them

- How to Diagnose a Bad Diesel Fuel Lift Pump

- Troubleshooting Diesel Fuel System Issues: Lift Pump Failures

- Diesel Fuel Lift Pump Symptoms: When to Replace

Maintaining a diligent inspection regime can empower diesel vehicle owners to recognize these issues early, potentially saving on costly repairs and ensuring a reliable operation of their diesel engines.

Conclusion

In summary, the significance of regular preventative maintenance for diesel lift pumps cannot be overstated. Throughout this article, we’ve highlighted the essential functions of lift pumps, the catastrophic consequences of neglecting their upkeep, and practical maintenance tasks that should be implemented routinely. By following a defined maintenance schedule that includes timely filter changes, monitoring of water separators, and ensuring fuel cleanliness, vehicle owners can effectively mitigate the risk of costly repairs and unexpected breakdowns.

Statistics reinforce the necessity of these practices, showing that 60% of diesel fuel system failures stem from maintenance neglect. Moreover, regular preventative care can extend the lifespan of lift pumps significantly, often doubling their operational longevity and enhancing fuel efficiency by up to 5%.

For further insights, consider these authoritative resources:

- Diesel Fuel Lift Pump Maintenance and Troubleshooting Guide – Diesel Power Magazine – A comprehensive guide covering diesel lift pump maintenance schedules, common failure symptoms, and troubleshooting procedures.

- Preventative Maintenance Schedule for Diesel Vehicles – Cummins Inc. – Official maintenance guide from Cummins covering critical diesel system components.

- The Critical Role of Preventive Maintenance in Diesel Engines – Cummins Inc. – An article discussing how preventive maintenance can significantly reduce downtime.

- Economic Impact of Preventive Maintenance on Diesel Engines – American Transportation Research Institute – Research demonstrating lower costs for fleets implementing comprehensive preventive maintenance.

To ensure optimal performance and longevity of your diesel system, we encourage you to take action now. Review your maintenance schedules, prioritize consistent inspections, and implement the recommended practices discussed herein. By being proactive about your lift pump maintenance, you can safeguard your vehicle against serious issues and enjoy a smoother, more efficient driving experience. Remember, when it comes to diesel systems, an ounce of prevention truly is worth a pound of cure!

Conclusion

In summary, the significance of regular preventative maintenance for diesel lift pumps cannot be overstated. Throughout this article, we’ve highlighted the essential functions of lift pumps, the catastrophic consequences of neglecting their upkeep, and practical maintenance tasks that should be implemented routinely. By following a defined maintenance schedule that includes timely filter changes, monitoring of water separators, and ensuring fuel cleanliness, vehicle owners can effectively mitigate the risk of costly repairs and unexpected breakdowns.

Statistics reinforce the necessity of these practices, showing that 60% of diesel fuel system failures stem from maintenance neglect. Moreover, regular preventative care can extend the lifespan of lift pumps significantly, often doubling their operational longevity and enhancing fuel efficiency by up to 5%.

To ensure optimal performance and longevity of your diesel system, we encourage you to take action now. Review your maintenance schedules, prioritize consistent inspections, and implement the recommended practices discussed herein. By being proactive about your lift pump maintenance, you can safeguard your vehicle against serious issues and enjoy a smoother, more efficient driving experience. Remember, when it comes to diesel systems, an ounce of prevention truly is worth a pound of cure!

Introduction

This section introduces the topic.

This infographic illustrates the importance of maintenance practices for diesel lift pumps, highlighting user adoption data, failure rates, and essential maintenance recommendations and statistics.

Maintenance Recommendations for Diesel Fuel System and Diesel Engine Care

Regular maintenance tasks for lift pumps is critical for ensuring their longevity and efficient operation in diesel fuel systems. Here are specific tasks, recommended intervals, and practical tips to keep your lift pump functioning effectively:

1. Filter Changes

- Primary Fuel Filter: Replace the primary fuel filter every 15,000 to 25,000 miles or after 500 hours of operation. This prevents larger contaminants from entering the system. Neglecting this task can result in fuel starvation and engine issues.

- Secondary Filter: Change the secondary fuel filter every 1,000 hours of operation to ensure optimal fine filtration. Monitor this more closely in dusty or high-sediment environments.

2. Water Separator Maintenance

- Inspect the water separator every 250 to 500 hours of operation. Regularly drain it to remove accumulated water.

- Replace the water separator filter annually or as needed, especially if visual inspections indicate contamination or sediment build-up.

- If warning lights activate for water presence, service the separator immediately, as this can lead to corrosion and microbial growth.

3. Tank Cleaning

- Clean your fuel tank every 2,000 hours or once a year to prevent microbial contamination and sediment accumulation.

- During cleaning, flush the entire fuel system, replacing any deteriorated components as necessary.

- If you observe any sediment at the bottom of the tank during inspections, prioritize cleaning to ensure the fuel remains uncontaminated.

Practical Tips

- Incorporate visual inspections of the lift pump and associated components monthly. Check for any visible leaks, cracks, or corrosion that could signal impending issues.

- Use OEM-approved filters and parts to maintain system integrity and optimize compatibility.

- Maintain a detailed maintenance log to track intervals, ensuring tasks are not overlooked.

- Implement biocide treatments every few years or as needed to combat microbial growth, especially if water contamination is evident.

By following these maintenance guidelines, diesel vehicle owners can significantly reduce the risk of lift pump failures, extend the life of their fuel systems, and avoid costly repairs stemming from neglect.